Best Pick And Place

In China

The best pick and place machine come from China. It has not only a high placement speed as compared to the other competitors, but also owns a really competitive price. Here are several types offered.

Description of Best Pick And Place In China

This is the BEST pick and place machine coming from China. It has not only a high placement speed as compared to the other competitors, but also owns a really competitive price. There are several types offered.

The PCB pick and place machine has two models, which can reach optimal 40,000 CPH as well as maintaining a placement precision of ± 0.05mm. The minimum component can reach 0402 (01005) mm.

The LED type pick and place machine has the highest mounting speed reaches 95,000 CPH with a ±2℃ placement accuracy, high production capacity.

Learn More About The China Pick and Place Info

1. What is the best pick and place machine in China?

What-Is-Surface-Mounted-Technology

The Pick-and-place machine has various names, except the P&P, we also can call it as SMT (surface mount technology) component placement systems commonly.

The best SMT pick and place machine in China evaluated into these key parameters, which are placement speed, applicable component, maximum PCB dimension, and performance stability.

In terms of these features, the pick and place machines that are able to meet these different requirements are available by ElectronicsTalk.

ElectronicsTalk has a wide product line of pick and place machines and it integrates them into one platform. Under the same level of placement accuracy, the first factor needs to consider is how fast the machine can mount.

The PNP-580M is just recommended to customers because it has an optimal mounting speed of 40,000 CPH which is the best solution among the same price of level.

Besides, it can also provide a stable mounting process without any issues when it comes to after-service period. That is also one of the key factors that need to be evaluated for pick and place machine situation in China.

On one hand, the standpoints above are more like specifically ideas.

On the other hand, it is for high speed, high precision mounting of a broad range of electronic components, such as resistors, capacitors, integrated circuits onto the printed circuit boards.

In real application, these boards are mostly in consumer electronics, personal computers, as well as industrial, automotive, medical, military and telecommunications equipment.

As to its simple working process, please see the following description, as a kind of robotic assembly device, it lifts a component off of a piece of tape by using a vacuum, rotates it to the right angle, then place it on a PCB.

Usually, It will take a few hours to set up a machine to build the assembly, but once everything is running, the mounting process will be very fast.

2. The market analysis of pick and place machine in China

2.1 The overview

Firstly, we would like to introduce an overview of the Chinese market.

- The SMT line firstly appeared in China in 1985.

In 1985, China introduced surface mounting technology production line which was so-called SMT line to manufacture TV products. S ince then, SMT has been used in the country’s electronics manufacturing industry for more than 30 years.

- By now, China has become the largest importer of pick and place machines.

At present, China is the largest and most important chip mounter market in the world.

However, a large part of mounters in China relies on import from foreign countries, especially high-end mounters, such as SONY, Assembleon, Siemens, Panasonic, FUJI, YAMAHA, JUKI, SAMSUNG, and UNIVERSAL.

To the 21st century, the development of the electronics manufacturing industry in China has been increased by 20% each year.

- Chinese electronic industry impulses the market development of chip mounter.

It, as the second-largest electronics industry, in the world, has become one of the pillar sectors of its national economy.

Then, the SMT technology acquired a rapid development along with the national growth of the electronics industry.

As for the regional demand of mounters in China, the Pearl River Delta takes more than half percentage, and the Yangtze River Delta takes about twenty percents.

With regard to enterprises’ property, there is a large number of enterprises from America, Europe, Japan, Taiwan, and HK investing in the mounter industry of Chinese Mainland and they are also the purchasers of SMT devices.

Pearl River Delta and Yangtze River Delta

- The future market trend in China and the global.

In this case, pick and place machine as the core equipment in the SMT production line, its quantity in China ranks in the top comparing with other counties, and which takes up above 40% market share in the world,

moreover, according to related data analysis, China will continue to be the largest market of SMT equipment especially the pick and place machine in the future.

Last but not least, though the mounter industry began at a late time in China, it has stepped into a new stage of deep researches and scale production.

What is more, domestic pick and place machine manufacturers have advanced on products’ quality and own price advantage.

Besides, the export tends are also increasing, hence, it is predicted that the output of mounters will rise up as well.

2.2 The import & export status

In this part, we can check the brief import and export condition of pick and place machines in China together.

- The import status.

With the wide range of application of SMT technology in semi-conductor, computer, internet communication, consumer electronics, and automotive electronics industries, which creates a huge market for the SMT devices in China,

Therefore, global equipment manufacturers tried their best to grape this opportunity to increase their investment in China.

Import & Export

Taking the period from 2010 to 2013 as an example, before 2013, the peak of the importing amount was in 2010, then there is a little decrease in 2012 and 2013.

The total imported pick and place machine amount is 8707 sets in 2013 valuing for 1.3 billion dollars, as well as Guangdong, Shanghai, and Jiangsu provinces, which are ranked the top three.

- The export status.

However, comparing with the import, the export of chip mounter is China is very few. In the same year, there were only 897 sets of devices exported from China.

Along with the breakthrough of the core technology in SMT equipment developing and manufacturing, the domestic manufactured SMT devices showed its advantages gradually.

What is more, India, Vietnam, Brazil, and East Europe will be the potential markets of the Chinese SMT industry.

2.3 The market segmentation

1) The electronics manufacturing industry

By application, the consumer electronics application is going to take the largest share of the market.

Then the consumer electronics application segment is also able to take the largest market share during the forecast period.

The major development responsible for the reduced size and weight of consumer electronics devices is the inclusion of the surface mount technology in these applications.

- The advantages of SMT

Comparing with through-hole packages, surface mounted components are smaller, thinner, and lighter, they only consume less space and power and contribute little to the total weight of the product.

- The application range of SMT

The SMT technology is the major production in the electronics assembly industry. Its main application area is industrial electronics and consumer electronics such as cameras, personal computers, communications, defense, and smart cellphones.

At present, the production of electronic products demands higher accuracy, higher speed as well as intelligence and flexibility, which improves the higher performance of the SMT equipment.

In order to meet the increasing demands of major customers, China domestic companies should work harder than ever.

- The LED industry

LED-industry-forecast

- The market prospect

LED lighting is a great potential industry. In 2015 the global LED market is estimated at 20 billion dollars, and China is the LED manufacturing base globally. LED chip mounter is the core device to gain the large-scale development of the LED industry.

- The advantages of LED lighting

LEDs have become an alternative light source to traditional fluorescent and incandescent bulbs. Comparing with the traditional bulbs, LED lighting has a longer lifespan and higher electrical efficiency. Besides, they are also more efficient than the traditional bulbs.

The electronics manufacturing industry is reaping the strength of the features of LEDs such as small size and low power consumption.

Comparing to the traditional lighting technologies, LED components can provide higher power efficiency, higher brightness, and lower carbon emissions.

On the basis of these factors, various government organizations have adopted LED lighting for installation in public places and government offices.

Compared with traditional lighting sources, LEDs are more cost-effective, and the use of automated SMT assembly of LED components bring high quality LED device. Most of the SMT placement machines are able to place multiple components on a PCB board at one time.

It helps in increasing the production rates and decreasing the labor costs for the reason that these equipment are automated, beside, it also reduces the errors during manufacturing process, thus driving the growth of the SMT market.

On the basis of the increased requirements for LED lighting, the market for the surface mount technology is also anticipated to grow in the coming future.

- Though the foreign brand is still in the leading position, domestic brand expects a chance.

However, the foreign brands still nearly take up the whole pick and place machines market especially the high-end devices, hence, the market share of the domestic market is really very low.

At present, because of the increasing of labor and overhead cost in developing countries, many LED factories in developed areas and countries begin to start their own assembly, for instance, Turkey and Spain.

Therefore, this is a brilliant chance for Chinese pick and place machines to present its presence in the international market with its affordable price and reliable performance.

- APAC

Asia-Pacific Region

APAC to account for the largest market size and is also anticipated to increase at the highest rate during the forecast period.

The increasing wireless communication standards and the rising requirements for 3G/4G/5G networks are spurring the demands for surface mounting technology in the telecommunication sector in the APAC region.

Over the years, China has become one of the fastest-growing economies in the world and its market for SMT is anticipated to grow primarily because of the large quantity of SMT manufacturing companies.

The booming development of the SMT market also is driven by the increasing of electric vehicles in the automotive sector in APAC.

Companies running in the surface mount technology market take many growth strategies, for instance, new product launches and developments, partnerships, agreements, collaboration, and acquisitions to acquire a competitive edge and enlarge their distribution networks.

- Healthcare application industry

Healthcare is the leading industry in triggering the growing anticipation of the surface mount technology equipment market in the world.

The boom of electronics and automated products in the healthcare sector offers the opportunity for the surface mount technology equipment market in this industry.

In addition, minimum operating and maintenance expense and ease of operation are the primary elements behind this segment’s huge needs.

On the flip side, growth in high investment cost of machinery is anticipated to negatively influence the increase of global SMT devices market.

3. Chinese pick and place machine manufacturer

3.1 The domestication in China

The appearing of pick and place machine in China can date back to 1995, since that time, major SMT equipment manufacturers are mainly engaged in low-end manufacturing.

In other words, they produce machines with low speed and low accuracy.

However, as time goes by, there are some equipment manufacturers emerged and hammered at producing high-quality machines with their own research and development ability, and Electronicstalk is one of these companies.

3.2 The major location of Chinese SMT manufacturers

South area in China

Cities in the south area in China like Guangzhou and Shenzhen are both the main areas where various SMT manufacturers and suppliers located in.

In these regions, you are able to find excellent providers including equipment, electronic components, electronics manufacturing services.

No matter you would like to search the second hand machine or the brand new types, here are plenty of vendors to meet your requirements.

3.3 ElectronicsTalk Company introduction

ElectronicsTalk has been dedicated to providing all-in-one SMT solutions for years. It integrated the most valuable suppliers globally to help the custoemrs solve any issues in the PCB assembly line.

All the options it can offer include PCB handling, placing, soldering, printing, inspection, conformal coating, and peripheral consumable series, etc. Custoemrs can find out their favorite equipment along with complete purchase information quickly here.

The one-stop service that it has been focusing on contains strict quality control, offering attentive pre-sales service in real-time at 24/7 to remove any purchasing barriers and post-sales service to keep improving the customer satisfaction.

- Products display

Full Auto SMT production line

This is a standard SMT line with loader, full automatic solder paste printer, conveyor, on-line SPI, BG buffer, pick and place machine, as well as reflow oven, on-line AOI machine, and unloader. It can meet the requirement of the middle-volume production.

3.4 SMT Pick and Place Machine in China

ElectronicsTalk is the leading SMT machine offering company in China, especially it can offer some of the best SMT pick and place machines with low costs. According to the spindles applied in the machine, there are 4 types of models that normally used in the production line.

- 4 Spindle Desktop Pick and Place Machine

As provided by ElectronicsTalk, DT-4H, is the fastest placement speed of desktop pick and place machine in the same class of products in the world. The Placement speed can reach 13,000 CPH.

Also, it can mount 0201 package easily as in real production line. The component range is large and it can handle all kinds of components, even they are in odd shape.

The core parts are imported from credible brands in the world, which ensure its stability and efficiency.

And it is specifically suitable for small-batch SMT assembly line.

- 6 Spindle Low-csot Pick and Place Machine

As another model provided by ElectronicsTalk, PP-6H, is aim at low-cost and higher placement speed of pick and place machine in China.

With the same specification as the overseas brands, it can compete with them by its lower cost.

In addition, the PNP-560M is owning an even higher placement speed, which can reach optimal 30,000 CPH. Not only speed level of it meet the low-to-medium production requirement, but also it has a 50 microns of placement accuracy.

Also, it can maintain a massive production performance with its stable machine configurations that are all imported from the famous brands such as Japan’s Panasonic.

- 8 Spindle PCB Pick and Place Machine

The most common and stable type of pick and place machine in China is by using the design of 8 spindles, and the PNP-580M is one of the best among the same class in China.

Firstly, the PNP-580M owning a maximum placement speed of 40,000 CPH, which is measured by strict standard. The placement speed is normally compete with the Samsung’s SM series of pick and place machine.

But, the most important factor as compared with Samsung’s machine is that the PNP-580M is very very cheap and affordable, which is perfectly suitable for the start-up who want to establish its own SMT line with limited budget.

Another feature of this machine is that it can improve the component recognition process efficiently by its 8 sets of Sony visual cameras and a single mark-point camera.

Besides, it has a wide range of applicable component range which enable to produce all kinds of LED chips and chips from 0402 package to large IC components. What’s more, its maximum PCB size can be 1200 mm long board, which further expand its application range.

- 12 Spindle PCB Pick and Place Machine

One of the fastest chip shooter for LED components in China is PNP-1500, which enable to handle 1500mm long board. It can be equipped with 12 spindles at once for massive production, which has a maximum placement speed of 95,000 CPH.

It is particularly used for LED production, the component range is from 0603 chip to all kinds of LED chips, and compatible for various of high power chips.

Moreover, the kind of pick and place machine work stably thanks to its solid base structure and firm marble table.

4. The LED chip mounter in China

4.1 China LED industry outline

In 2018, the total value of the China LED market was US$ 16.4 Billion.

- The reasons for the rapid market expansion of LED lighting in China

LEDs are able to provide various advantages than traditional lighting products, for example, longer shelf life, environment-friendly, controllable, higher efficiency, emits no radiation as we use lower power.

Comparing with incandescent bulbs, LEDs are highly energy-efficient and consume significantly less power.

On the basis of their numerous advantages, LED lights rapidly take the place of traditional lighting products in China.

- China is the major market player.

The Chinese government is also playing a major role in pushing the increasing of the industry by providing large scale subsidies for the adoption of LED products.

What is more, the Chinese government has also forbidden incandescent bulbs in the country since the National Development and Reform Commission first declaimed the country’s incandescent bulb exiting the market on November 2011.

Some of the other crucial elements driving the LED sector in China include reducing prices, local energy savings targets, infrastructure growth, and rising urbanization levels.

China LED market

Since the LED lighting industry has stepped into the mature period, manufacturers are anticipating a larger market requirements for high-end lighting, such as professional lighting and healthy lighting.

Additionally, automotive lighting, UV-LED and digital display (video wall) will be the major driving factors for LED industry development in the coming future.

With regard to the general development of the Chinese LED sector, taking advantage of production capacity and OEM orders.

Furthermore, LED suppliers from China mainland have all acquired rank improvement in 2018 and manufacturers like NationStar, MLS, Jufei and Hongli are acquring increased revenue unceasingly.

4.2 LED Chip mounters

- The LED chip mounter market in China

- The revolution in the LED industry

Within the past few years, there has been a reform in the lighting industry that has carried over to the surface mount technology assembly line.

This revolution or change in the lighting industry has some very promising outcomes already in practice.

Besides, many more companies are looking to adopt the LED technology into their product portfolios.

Due to a number of companies are looking to expand their portfolio to include LED fixtures, there has been an growth in the number of companies that have started set up their own SMT lines.

As well as a significant quantity of contract manufacturers to meet this new industries requirements.

China SMT Chip Mounter

- The auto pick and place machine application in LED industry

On the basis of this surge in the new style of lighting, the manufacturers require the automated pick and place process to achieve the outputs that are being expected,

hence, there has been a sudden growth of companies that have faced issues about the pick and place process with less than desirable results. The automated pick and place systems have been applied for highly accurate and high-speed placement of a wide range of electronic components.

A major element in the automated pick and place manufacturing for SMDs (surface mount devices) is that most of the components previously being placed have been in use since the 1980s.

These process speeds and parameters specified have been concentrated on hard or solid epoxy molded, flat topside packages, like resistors, capacitors, and integrated circuits.

Over the multitude of years, since the origin of the automated pick and place system, the parameters applied to take control of the equipment have been refined.

At present, there is a new product that appeared in this industry, it may demand some adjustments, especially when LEDs with a glass or soft silicone molded dome are introduced.

- The requirements to LED pick and place machine

The contain of high-power LEDs in the pick and place procedure introduced many potential of errors that can affect the final performance of the pick and place system.

- LED mounting needs the specified pick and place machine.

LEDs demand specific process specifications for the pick and place equipment to make the optimization of the system’s performance. This is due majorly to the dome material and weight distribution of the LED component.

Pick and place manufacturers have acquired a great deal of knowledge within the past 25 years picking various categories of components.

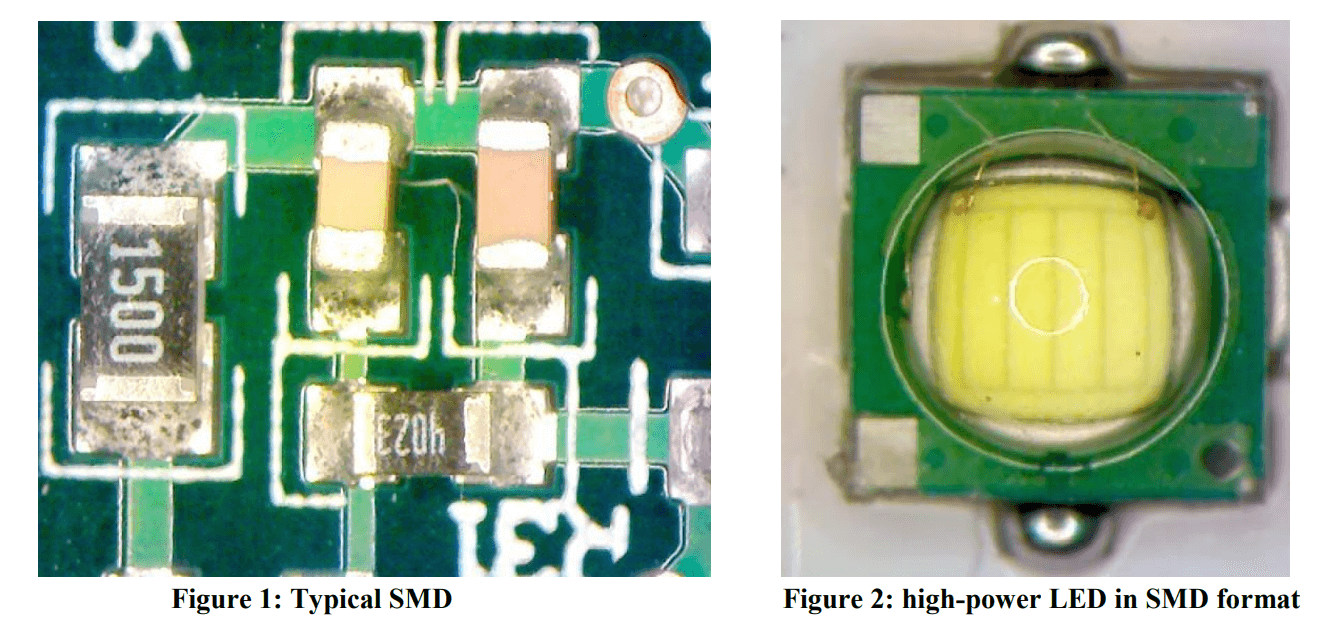

Figure 1 shows a typical example, while the figure a displays a high-power LED with soft molded silicone or glass dome,

It has been in use for only about 5 years, and there is still a large amount of pick and place process refinement to make sure that these components can be mounted similar to the SMDs already being used.

Normal Chips and LED chips

- How to achieve successful LED chips mounting?

For solid-state lighting products to be successful, not only are the best and brightest LEDs on the market demanded,

But the knowledge and support to deal with these components in a high-speed, highly accurate manufacturing process bringing in high outputs, low defect rates, and without damages to LEDs are critical.

There has been a large quantity of work by a lot of pick and place manufacturers to support the industry in identifying the best options available,

Besides, in order to maximize the performance of their systems, they need to make modifications, and adjustments to minimize wrong picks and increase outputs.

- So, what are the so-called wrong picks?

Wrong-picks is the term commonly applied to describe what happens when a component is not picked properly out of the carrier tape pocket like feeders, trays, or tubes.

A mix-pick can be due to a various kinds of reasons that will be discussed. These mix-picks can result in a large rate of attrition,

Therefore it will cause delays in production as well as increase the cost associated with the fixture.

- The features of LED pick and`place machine

- Chips requirements:The LED chip mounters should be able to meet the placement accuracy of 3014, 2835, 3528, 5050, 5630, 5730 bulb chips. Comparing with traditional pick and place machine, the LED chip mounter does not need to have very high accuracy.

However, it indeed requires high machine performance such as machine running stability, speed, operability, and the ability to handle flexible component sizes.

LED Chips

- Intellectual methods: As a pick and place machine specialized in LED mounting, various sensors with brilliant performance must be equipped to fully collect data during the mounting process, which makes sure the stability and reliability of the whole mounting procedure.

- Speed requirements:though there areno high accuracy demands, the LED mounter should have a high speed, the lowest speed requirement is 18000 CPH.

- Easy to learn and operate: this can reduce the training time for the machine operators and can reduce the possibility of mistakes in operating and raise the productionefficiency and the products quality.

- The long–board handling ability: comparing with traditional printed circuit board, generally the LED panel hasalonger length, hence, in order to fulfill the production needs, the LED mounter better to meet the 1.2-meter board mounting demands.

4.3 The present technical development condition of LED chip mounters in China

As the great potential of the fourth generation of the lighting source, Chinese domestic LED pick and place machine has achieved a leapfrog development within the past years under the support of the Chinese government.

From the previous boom of the LED display to nowadays LED commercial lighting, indoor lighting, outdoor lighting, and various lighting projects, the LED products have developed from the single hot product into the applications and popularity in the whole LED sector.

At present, most China domestic LED chip mounters are able to mount the 1.2-meter board, and the majority of them adopt the platform frame and the two swing arms to pick and place the LED chips.

Frankly speaking, now, China domestic LED chip mounters are still in the initial stage. They mainly meet the simple production demands for small and medium enterprises.

4.4 The development trend of LED chip mounters in China

LED chip mounters play an essential role in the LED assembly industry, also they are the most expensive and takes the largest investment and the most advanced technology among contemporary electronic assembly equipment, besides, they also have the greatest effects on the total outputs and productive efficiency of the SMT production line.

Furthermore, most faulty and the speed limits are also determined by the LED mounters. Hence, the quantity and performance of the LED pick and place machine have become the critic symbol of electronic manufacturing in a company, a region even a country.

- Higher mounting accuracy

Without sacrificing the accuracy, flip-over no packaging process will be applied in LED chip mounters. It can help reduce the packaging costs and shorten the production cycle, then let the LED products enter the lighting industry with high performance and cheap price. Flipping-over no packaging process is a potential trend in future technology.

- The higher automation

The development and improvement of information science and technology have greatly promoted the level of automation and achieved a higher level of automation such as self-learning, self-organization, self-maintenance, self-repair from the original automatic control, automatic regulation, automatic compensation, automatic discrimination, etc..

At the same time, automatic numerical control device like the pick and place machine, the efficiency of software programming is also crucial to improve the efficiency of the equipment, the development of more powerful software function system can reduce the time of manual programming, then can greatly shorten the invalid working time, and improve the production efficiency at last.

- Improving the equipment frame and the working mode

When the mounting speed of LED mounter reaches the bottleneck gradually, it is a good idea to improve the structure of LED mounter. For example, on the basis of retaining the performance of the traditional single-way, the PCB conveying, positioning, detection and mounter of one LED mounter can be designed into a double-way structure.

This two-way structure can work both synchronously and asynchronously. The synchronous mode is to send two PCB of the same size into the mounting area synchronously from the double-track conveyor for mounting, while the asynchronous mode is to send PCB of different sizes to the mounting area respectively. Both of these working methods can improve the production efficiency of the machine.

- Flexible and modular structure development

The development of society has promoted people’s living standards and cognition, and personalized demand will be an important strategic means for the market in the future. The opening of the era of e-commerce gives us more enlightenment that the traditional brick-and-mortar business model is more for new product experience.

In the future, the manufacture of electronic products will face such challenges as variety, small-batch, and short cycles in order to meet the personalized demand of the market. An effective way to adapt to this trend is the flexibility of mount equipment.

For example, the host of LED mounter can be made into a standard device and equipped with a unified platform and a common user interface, while the functions of the dispensing machine can be made into a functional module group, besides, the module group has different functions.

According to the mounting requirements of different components, it can achieve placements with different precision and speed to fulfill the higher efficiency. When the user has a new requirement, then they can add the new function module according to the need.

The flexibility of LED mounter is the flexibility of mounting in actual production. It includes the ability to adapt to different PCBA products, the ability to take into account the mounting accuracy and speed, the ability to quickly carry out production conversion, and the ability to upgrade.

Moreover, Flexibility is a scheme that can maximize the use of existing resources to create the best economic benefits, so flexibility is a kind of conceptual, dynamic, relative description of equipment characteristics.

- Intelligent development

Intelligent Development

With the rapid development of internet technology, the explosive growth of mobile intelligent terminals, and the youth of consumer groups, intelligence will be inevitable in the development of the electronic industry, especially in the home appliance industry.

The concept of intelligence has appeared in our lives very frequently, and the intelligence of products is the most promising future market. Similarly, in the manufacturing industry, the intelligentization of manufacturing equipment is also the most promising development trend of manufacturing technology.

Intelligent LED placement machine has the following characteristics: man-machine integration, self-learning, self-organization, self-maintenance, self-repair, super flexible, etc., as well as it will extremely improve the level of mental labor automation, and reduce the errors during the production process, so as to improve final efficiency and productivity.

Future LED placement machines will have a higher level of human-like thinking ability on the basis of computer intelligence technology, and it will able to make the analysis, judgment, reasoning, and decision making to the whole process of mounting.

Besides, it will be capable to put forward quickly the most suitable flexibility solution through the collection, storage, sharing, and inherit the intelligence of human experts. Furthermore, the precision and intelligence of LED mounter will have a great influence on the future production and technology of LED.

- Eco-friendly development

In recent years, the concepts of greening and environmental protection have gained new connotations. The so-called environmental protection is in a broad sense, which not only includes the protection of the natural environment, but also the social environment and the production environment, as well as the physical and mental environment of the producers.

The development of human society is bound to main-kind, man and machine, people and society, the harmony of man and nature. Therefore, the future design, manufacturing and recycling of LED chip mounters must consider the impact on the environment. It is better to fully consider the improvement of the material utilization at the beginning of the machine design, which allows users to maximize investment return.

5. Conclusion

China will be oriented to one of the SMT equipment manufacturing powers in the Asia-pacific region to form a new pattern of world production of SMT equipment. Besides, localization SMT equipment manufacturing development strategy must foster strengths and circumvent weaknesses, focused, and all the manufacturers should steadily improve the technical contents of their products. `

On the basis of placement machine research and development, the government policy support, and the investment fund, China domestic SMT machine manufacturing will definitely make new breakthroughs. What is more, cooperation and innovation are crucial ways for China domestic SMT enterprises to be outstanding in the global SMT equipment market.

Solving the PCBA industry biggest problems

Working with ElectronicsTalk offers you high-standard PCBA products that are supplied from credible manufacturers in attractive cost.

We dedicate to provide the best customer support, its the vital aspect of our company philosophy.