PCB Conformal

Coating

ElectronicsTalk provides a complete, high-precision fluid solution during PCB coating.

With up to three models of selective conformal coating machine, which all accurately realize the selective spraying process of coating area.

The UV curing and IR reflow oven have a high performance of temperature control with fantastic performance. Besides, the board handling such as auto loader & unloader, visual inspection, reject conveyor, are available.

PCB Conformal Coating Solution

Conformal coating is a protective coating that is applied to printed circuit boards (PCBs) to shield them against moisture, dust, chemicals, and temperature extremes. This coating acts as an insulating barrier and helps extend the life and reliability of PCBs. With the miniaturization of electronics and the advancement of technology, conformal coatings have become indispensable in the electronics industry.

Conformal coatings, also known as conformal films, are thin polymeric coatings applied on printed circuit boards (PCB) and electronic assemblies. The purpose of conformal coating is to protect the components and circuitry from moisture, dust, chemicals, and temperature extremes that can cause current leakages, electrical failures, and corrosion.

Conformal coatings are called “conformal” because they conform to the contours of components and circuit boards, creating a protective covering. The coatings are made of insulating polymeric materials like acrylic, silicone, urethane, perylene, epoxy, etc. When applied correctly, they form a uniform coating just a few millimeters thick over the entire assembly.

The benefits of conformal coating include:

– Increased resistance to moisture, fungi, dust, and corrosion

– Protection against electrical shorts from condensation and surface contamination

– Prevention of dendritic growth and tin whiskering

– Improved product reliability and lifespan

– Aid in meeting safety requirements and industry standards

There are several types of conformal coatings available, and the choice depends on the application, operating environment, and requirements. The common types include:

Acrylic Coatings

Acrylic conformal coatings provide good moisture and chemical resistance at an affordable cost. They cure rapidly at room temperature and can be easily repaired. Acrylics are suitable for most PCB applications but have limited resistance to solvents.

Silicone Coatings

Silicone conformal coatings offer excellent moisture, chemical, thermal, and UV resistance. They retain their flexibility over a wide temperature range but require elevated curing temperatures. Silicones can be difficult to repair and require primers on some surfaces.

Urethane Coatings

Urethane conformal coatings provide high abrasion and chemical resistance. They have good dielectric properties over a wide temperature range. However, urethanes are relatively expensive and require long curing times.

Parylene Coatings

Parylene conformal coatings are deposited through vapor deposition, enabling uniform thin films over complex surfaces. They offer excellent penetration, dielectric strength, and moisture resistance. However, parylene deposition requires specialized equipment.

Epoxy Coatings

Epoxy coatings provide superb moisture, chemical, and abrasion resistance. They have good dielectric properties but require elevated curing temperatures. Epoxies are relatively rigid coatings with limited repairability.

Applying Conformal Coatings

Conformal coatings can be applied on PCBs through several techniques:

Dipping

Dipping involves submerging the PCB in a conformal coating bath. It allows the coating of complex geometries but can result in uneven coatings. Drip drying and fixture rotation help achieve uniform coats.

Spraying

Spray coating using pressurized spray guns allows fast application on high-volume production lines. Automated spray systems with programmable spray patterns provide excellent control of coating thickness and coverage.

Brushing

Manual brushing lets accurate and selective application on specific components or areas of a PCB. Brushing is suitable for prototypes, rework, and touch-up applications. However, it can result in uneven coats.

Dispensing

Automated dispensing systems use programmable needle valves to deposit precise dots or beads of conformal coating. Dispensing allows accurate coating of selective components and leads to little material waste.

Vapor Deposition

Parylene coatings are applied through vapor deposition under vacuum conditions, enabling excellent penetration and pinhole-free coatings of uniform thickness. However, it requires costly specialized equipment.

Selecting Conformal Coating Materials

The selection of conformal coating material depends on several factors:

Operating environment – Coating must be compatible with temperature, humidity, chemicals, etc. Silicon and parylene suit high temperatures while acrylic suits room temperatures.

PCB material and components – Compatibility of coating material with PCB substrate, components, solders, wire insulation, etc must be ensured.

Coating thickness required – Thinner coatings (25-75 microns) suffice for most applications while thicker coats (75-175 microns) suit extreme conditions.

Repairability – Acrylic and some urethanes are easiest to repair while silicone and perylene are difficult to repair.

Process considerations – Coating materials must suit the application method used. For example, viscosity must suit spray, dip, or dispense application.

Safety approvals – Coating must meet flammability ratings like UL94 V-0 and IPC standards.

Cost – Acrylics are economical while parylene and some urethanes are expensive.

The component datasheets, material compatibility charts, and conformal coating supplier recommendations should be referred to for selecting the right coating.

Step-by-Step Conformal Coating Application

Follow these key steps for proper conformal coating application:

1. Surface Preparation

The PCB must be thoroughly cleaned to remove contaminants like moisture, grease, and particulates which can cause coating defects. Solvent cleaning and plasma/laser surface activation help improve coating adhesion.

2. Masking

Areas that should not be coated like connectors, test points, switches, etc. must be masked using plugs, caps, tapes, and latex. Masking tackles problems like inserted connectors and avoids rework.

3. Coating Material Preparation

Coating materials like acrylics, urethanes, and silicones typically contain two parts (resin & catalyst) that must be mixed as per the manufacturer’s instructions before application. Pre-heating the PCB helps lower coating viscosity for uniform coats.

4. Coating Application

The mixed coating must be applied according to the selected application method – dip, spray, brush, dispense, etc. Proper fixturing ensures boards remain static during coating. Automated precision spray and dispense systems allow accurate coating thickness.

5. Curing

The applied coating must be cured as per the manufacturer’s recommended procedure to ensure full cross-linking. Insufficient curing can lead to tacky and weak coating unable to protect the PCB. Curing is done by heat in ovens, or at room temperature.

6. Unmasking and Touch-up

After curing, all masking materials must be removed. Any minor defects should be repaired with a touch-up coating. The coated board should be visually inspected under adequate lighting for any flaws.

7. Post-Cure

Additional heat curing for a few hours may be recommended by the manufacturer to ensure a complete cure. Post-curing enhances the protective properties of the coating.

Conformal Coating Safety Precautions

Conformal coatings contain volatile organic compounds (VOCs) and solvents that require safe handling. Take the following precautions:

– Wear nitrile gloves, eye protection, and respirators to prevent skin/eye contact and vapor inhalation.

– Coating application and curing must be done in well-ventilated areas to prevent vapor buildup.

– Flammable solvent-based conformal coatings require explosion-proof environments and spark-free tools.

– Coating containers must be properly closed to prevent evaporation and ignition hazards.

– Avoid contact of coatings with water (moisture catalysts cure reactions).

– Hazardous uncured coatings should be disposed of per local environmental regulations.

With proper handling, conformal coatings provide excellent protection for PCB assemblies. However, no coating can prevent damage from extreme over-voltages or physical damage. Regular inspection of coated boards for damage is recommended to achieve maximum reliability.

Types of Conformal Coating machine

Selective Conformal Coating Machine

The three models of selective conformal coating machine are classified according to their working method and performance.

Adopting 3/4 axis of driving mode and 2 standard valves which enable auto-switching and coordination, can realize high density and complex PCB spraying process.

Imported major parts allow the system positioning accuracy to achieve 20 micron and high-speed and stable transmission control system.

Besides, the valve of the CC-8402 can be tilted 45°, rotated 360°, and is automatically cleaned, which is an unique design except for the other two models.

Conformal Coating Board Handling

Unique design for conformal coating line solution, there are many board handling machines provided as well. All of the handling machines are support up and down transmission conveyor system, which is particularly applied for the automatic coating process when top-bottom sides

of board needed to coating.

UV Curing Oven

UV curing oven can optimize the curing process by utilizing ultra-violet. Equipped with stepper motor and chain conveyor, owning higher transmission speed and width adjustment automatically.

With PLC and touch screen system, ensure stable control ability. The equipment has the function of board entry and exit detection, which can observe the number of boards in the equipment and the conveying situation at any time.

Also, it carries two sets of electronic dimming light sources at the same time, and the UV light intensity can be adjusted accordingly.

Infrared

The chain conveying method is adopted, and the width between the chains can be adjusted arbitrarily in the range of 50-450mm, which can meet the various connection methods of customers.

The chain uses stainless steel extension pin chain, ensure a solid and stable structure. Use the PID temperature controller and button control to achieve precise temperature control in 2 temperature zones. It has 2 temperature zones, each with 6 heating pipes, to minimize energy consumption.

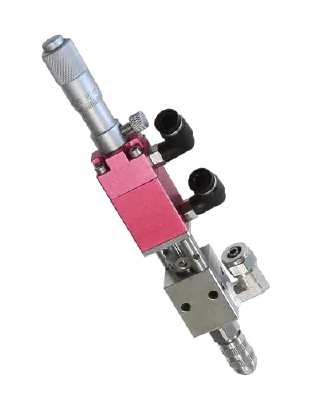

PCB Coating Spray Nozzle

Supporting 9 types of PCB coating spray nozzles or valves varied as their different functions. The block type dispensing valve, small atomizing spray valve, large atomizing spray valve, needle atomizer, extended needle atomizer, three mode injection valve, water curtain valve, back suction valve, nano-meter spray valve.

Conclusion

Conformal coatings shield printed circuit boards from environmental and mechanical damage, improving product life and reliability. With Miniaturization and denser designs, conformal coatings have become indispensable in electronic devices and systems operating in demanding environments.

While several coating options exist, acrylic, silicone, and urethane coatings are the most popular choices for PCB protection. Automated precision spraying and dispensing allow cost-effective high-volume PCB coating with minimal material wastage and high quality.

With the proper selection, application, and curing, conformal coatings serve as a key protection against contaminants and conditions that result in premature PCB failures. However, coatings must be regularly inspected for damage due to their limited protection from over-voltages and physical damage.

Solving the PCBA industry biggest problems

Working with ElectronicsTalk offers you high-standard PCBA products that are supplied from credible manufacturers in attractive cost.

We dedicate to provide the best customer support, its the vital aspect of our company philosophy.