High-Speed SMT Reel X-Ray Counter for Comprehensive Material Detection

Revolutionize Your Inspections with the MirXT-160

High-Speed SMT Reel X-Ray Counter – Precision, Efficiency, and Reliability in Every Count!

SMT X-Ray Counter

Experience and Capabilities

- Advanced X-ray point systems designed for rapid counting and inventory management of various materials.

- High-precision, non-contact counting to prevent chip damage or loss.

- Flexible tray compatibility (7-17 inches, JEDEC trays, moisture-sensitive bags) for diverse material types.

- Intelligent anti-interference counting algorithms ensuring accurate detection within 8 seconds.

- Seamless integration with ERP, MES, and WMS systems for streamlined operations and data management.

- Automated operations with six-axis robot arms and machine vision for efficient labeling and material handling.

Industries Used-in

- Integrated Circuit and Electronic Manufacturing

- New Energy Batteries

- Precision Metal Components

- Intelligent Materials

- Surface-Mount Technology (SMT) Industry

- PCB Manufacturing

- BGA and SMT Assembly

Use Applications

- Rapid counting and inventory management of resistive, capacitive, and IC materials

- High-precision chip counting with non-contact methods to prevent damage

- Flexible tray compatibility (7-17 inches) for diverse material types

- Automatic labeling and material grabbing with high recognition accuracy up to 0.01mm

- Support for unmanned loading via Automated Guided Vehicles (AGVs)

- Plate induction technology to prevent mislabeling

- Efficient detection and counting of single disk or multi-disk materials with feeding options for 1-4 stations

Unbeatable Offer Challenge!

Unbeatable Offer Challenge!

Tell us your needs,

Get the UNMATCHED Quote on X-ray Solutions in the Industry!

– guaranteed to meet your exact needs and budget!

ELT’s Battery X-Ray Machines

Specs Overview

Model Navigation

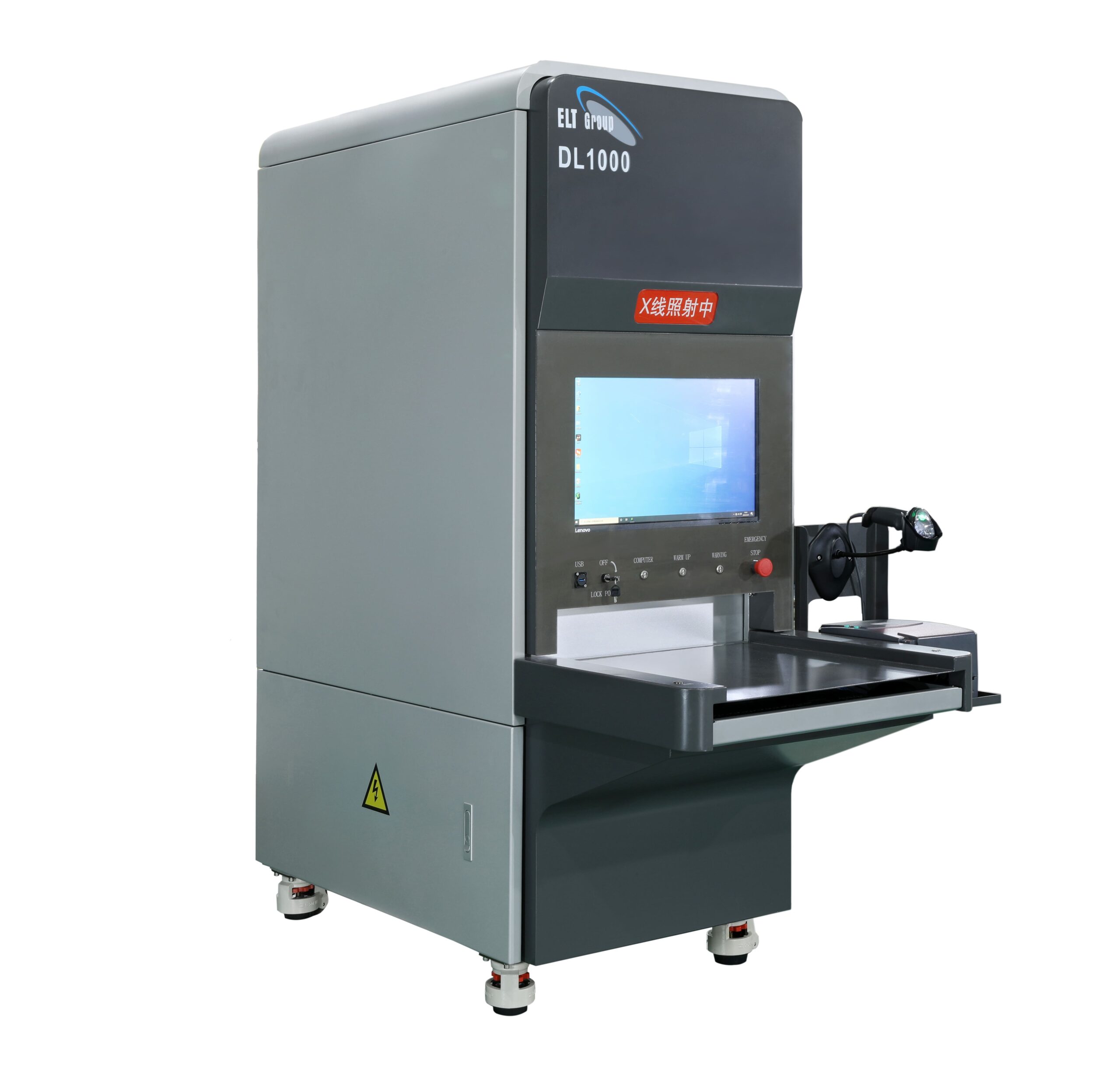

Offline X-ray Counter | DL1000:

Our off-line X-Ray point system is designed to cover all resistance, capacitance, and IC materials, providing rapid and accurate counting and inventory management for a variety of material trays.

Functions and Features

- Versatile Material Coverage: Capable of handling all resistance, capacitance, and IC materials for efficient counting and inventory.

- Wide Compatibility: Suitable for 7-17 inch trays, JEDEC trays, C moisture sensitive bags, and other materials, ensuring fast and precise detection.

- User-Friendly Operation: Simplifies personnel operation and reduces working space requirements.

- Advanced Counting Algorithm: Features an intelligent anti-interference counting algorithm for accurate identification of single disk or 1-4 disk materials, completing detection in just 8 seconds.

- Anti-Mislabeling: Equipped with plate induction technology to prevent mislabeling.

- System Integration: Supports connections with ERP, MES, and WMS systems for enhanced data management and operational efficiency.

Detailed Specification

| Overall Condition of Equipment | Equipment Size | about 730*1050*1875mm(Footing included) |

| Gross Weight of Equipment | about 700Kg | |

| Supply Voltage | AC110/220V, 50/60Hz | |

| Gross Power | Max 1.5KW | |

| Loading Method | Manual placement, automatic pallet in and out | |

| The X-Ray Tube | X-Ray Tube Voltage | 80KV |

| X-Ray Tube Current | 1000uA | |

| Detail Resolution | 15um | |

| Detector | Imaging Area | 422mm*422mm |

| Pixel Size | about 150um | |

| Pixel Matrix | 3072*3072 Pixels | |

| A/D conversion digits | 16bits | |

| Check item and size | Maximum Size of Tray | 380mm |

| Minimum Size of Tray | 180mm | |

| Maximum Plate Thickness | about 85mm (Images are not allowed to overlap) | |

| Minimum Plate Thickness | 5mm | |

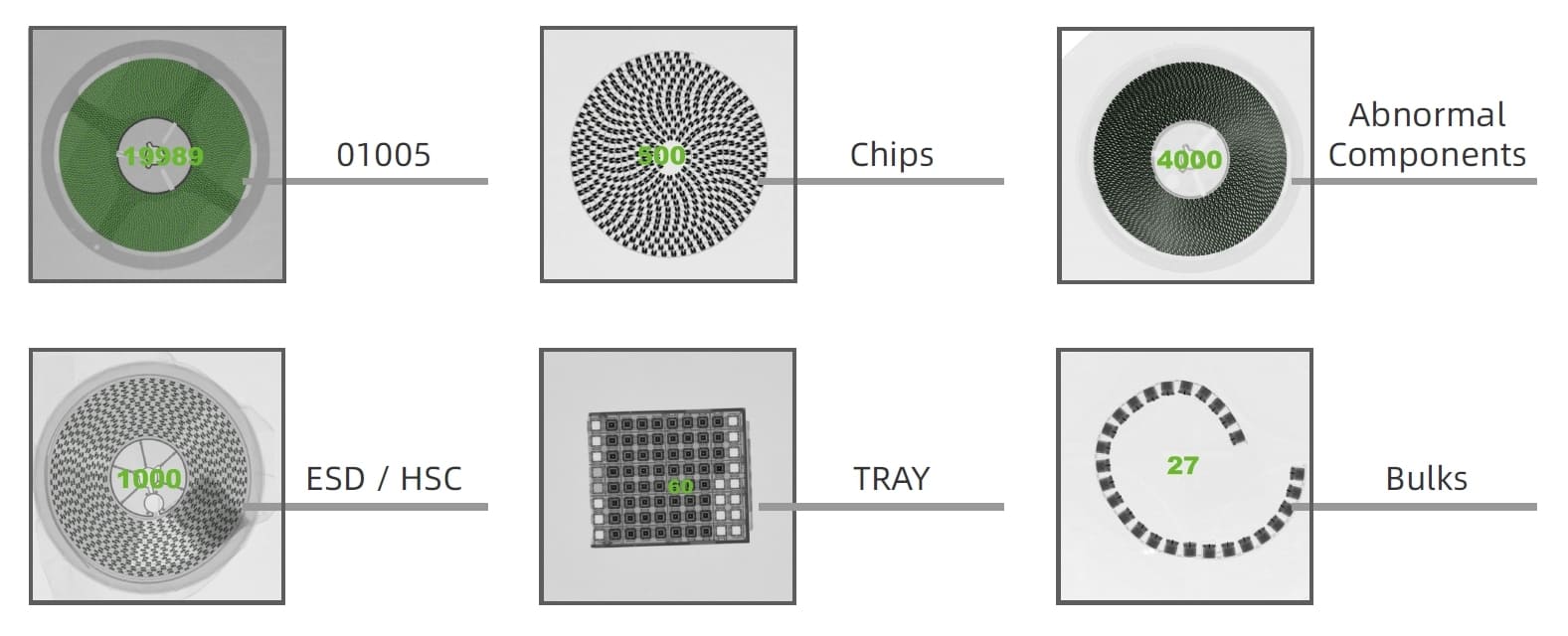

| Compatible Minimum Element | 01005 | |

| Other Compatible | Strip shape material, Box loading bulk material | |

| Counting Time | about 8 s/disc (4 discs can be detected simultaneously) | |

| Counting Accuracy | 01005 achievable 99.8% 0201or up to 99.9% | |

| QR Code Scanning | Can be configured one -dimensional, two – dimensional bar code scanning gun | |

| Label Printing | It can print material coding and counting results in real time |

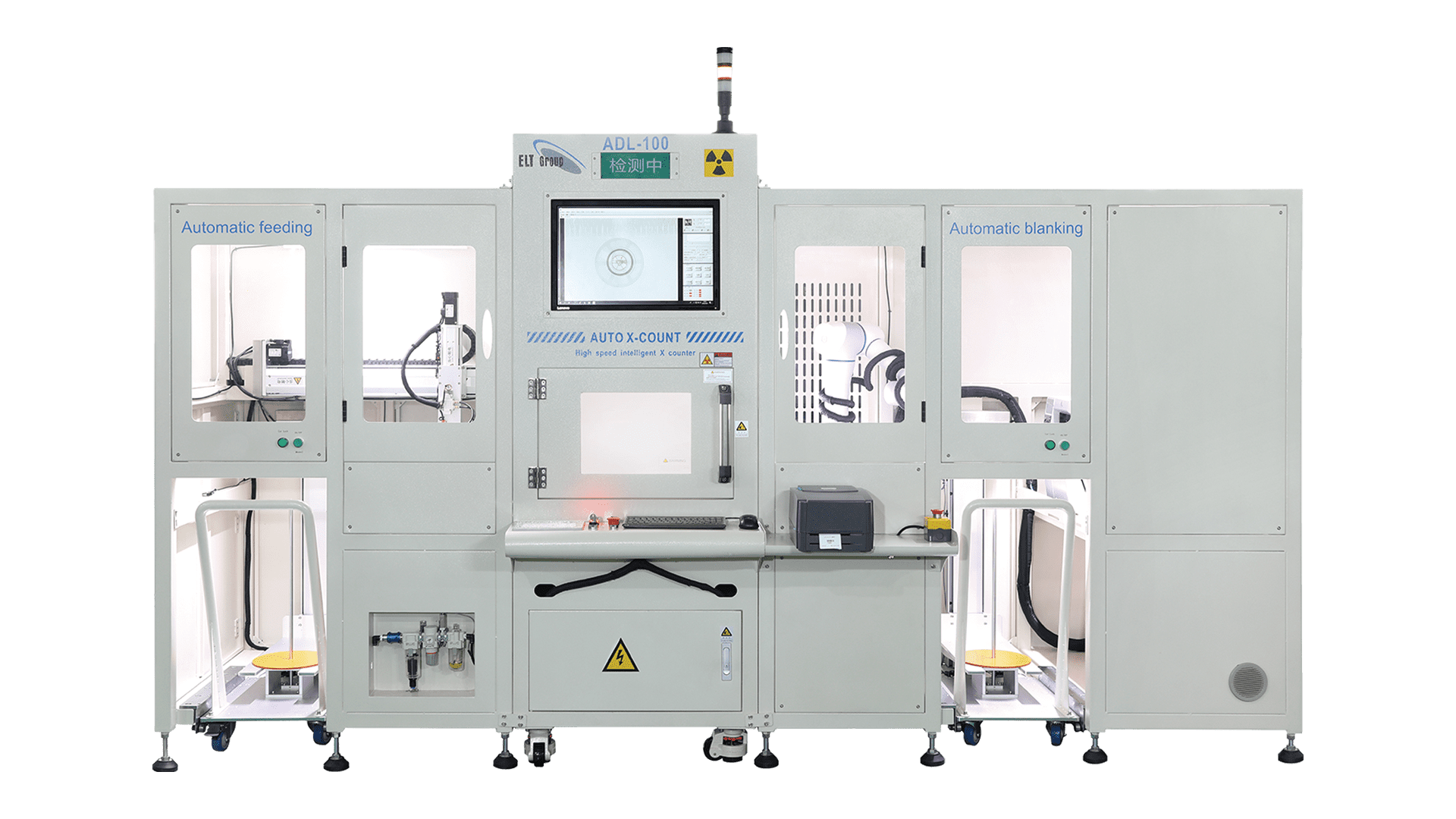

Online Automatic X-Ray Counter | ADL100:

Introducing our fully automatic X-Ray point system, designed for rapid counting and inventory of resistive, capacitive, and IC materials. This advanced solution ensures high precision and efficiency in handling various types of trays, optimizing your production and inventory processes.

Functions and Features

- Versatile Counting: Covers all resistive, capacitive, and IC materials, enabling fast and accurate counting of various tray types.

- High Precision: Ensures fast, high-precision chip counting, significantly reducing labor costs.

- Non-Contact Counting: Guarantees no chip damage or loss during the counting process.

- Flexible Feeding: Offers flexible feeding methods with 1-4 stations to suit different operational needs.

- Advanced Robotics: Equipped with a six-axis robot arm and machine vision for automatic labeling and material grabbing, providing high recognition accuracy and flexibility.

- Unmanned Loading: Compatible with AGV loading for seamless, unmanned operations.

- System Integration: Supports connections with ERP, MES, and WMS systems for streamlined data management and operational efficiency.

- Space-Saving Design: Designed without an NG warehouse, maximizing space utilization.

Detailed Specification

| X–Ray Tube | Tube Voltage | 80KV |

| Tube Current | 150uA | |

| Detector | Imaging Area | 427mm*427mm |

| Pixel Size | about 48um-75um | |

| Pixel Matrix | 3072*3072 Pixels | |

| Check Item and Size | Maximum Size of Tray | 380mm |

| Minimum Size of Tray | 180mm | |

| Maximum Plate Thickness | 85mm | |

| Minimum Plate Thickness | 3mm | |

| Compatible Minimum Element | 01005 | |

| Counting Time | ≤10s disc | |

| Counting Accuracy | 01005 Reachable 99.8% 0201 Reachable 99.9% up | |

| Upper (Lower) Feeder

(One for each) |

Material Size | Diameter 7-13°-15 |

| Material Height | Thickness 8mm~85mm | |

| Speed | 5-10 s per disc | |

| Feed Type | There are two stations in total, each station can store about 50 materials (according to the height of 10m per plate), and two stations are recycled. | |

| Stacker car | Automatic continuous feed to the intelligent point machine, connected to the intelligent point machine front end. |

Application Product Samples

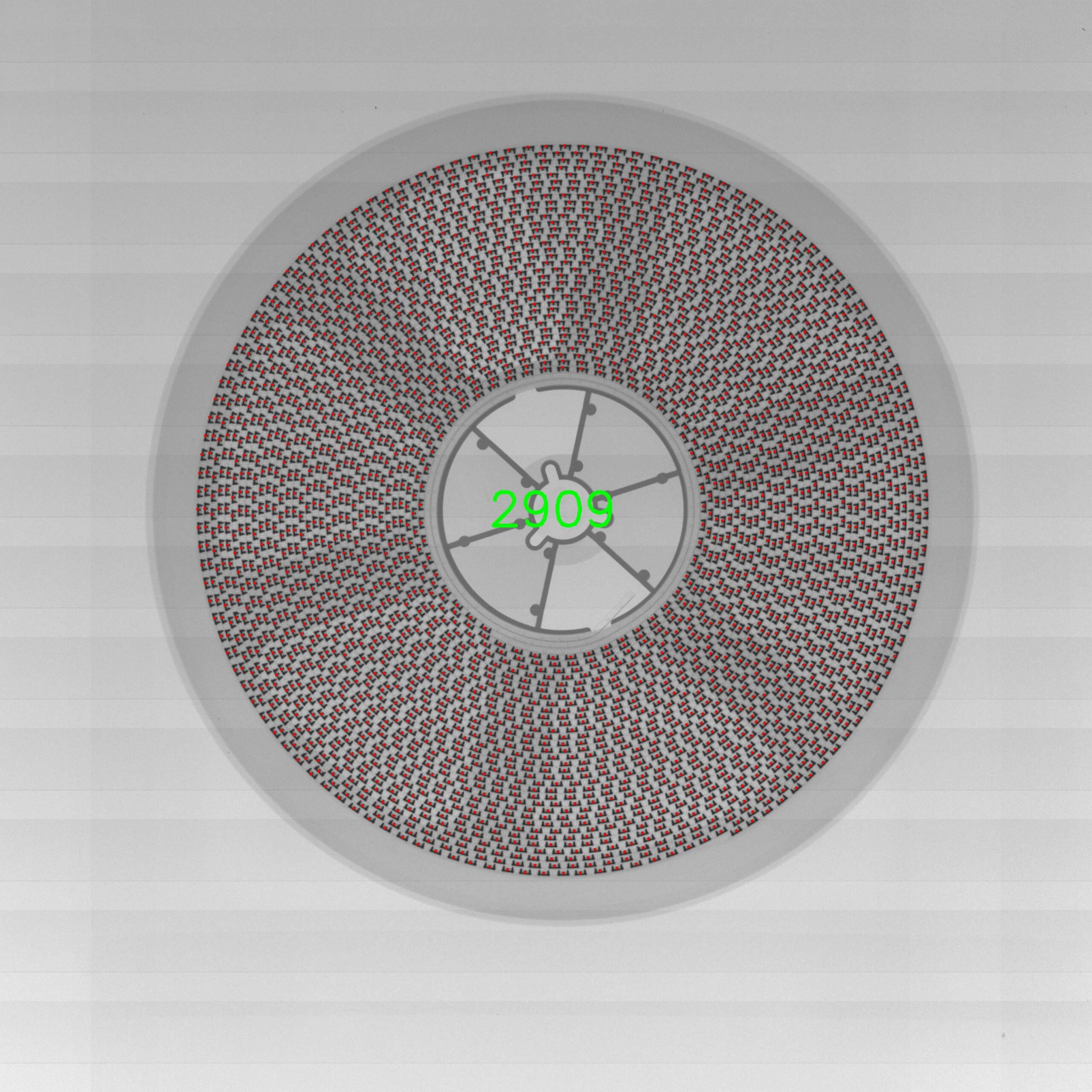

X-Ray Inspection Images

Elevate Your Component Counting with ELT’s SMT X-Ray Reel Counters

Revolutionary AI-Powered Counting Software

- Are you looking for high-end X-ray counters for counting PCB chip reels? Look no further than ELT’s SMT X-ray SMD component counters! These advanced products are designed to meet the demands of modern manufacturing with unmatched speed, accuracy, and customization options.

Key Benefits

- Lightning-Fast Counting: Minimum counting time of just 9 seconds.

- Versatile Reel Handling: Supports PCB reels up to 17 inches in size.

- High-Resolution Imaging: Advanced image system for clear, precise counts.

- Intelligent Algorithm: Achieves 99.99% repeat accuracy.

- Customizable Solutions: Tailored to your specific requirements.

Unmatched Speed and Efficiency

- ELT’s SMT X-ray Component Counters are engineered for lightning-fast processing speeds, achieving a minimum counting time of just 9 seconds. This efficiency ensures that you can handle high volumes with ease, significantly enhancing your productivity.

Versatile Handling Capabilities

- Our SMT counters accommodate a large PCB reel size range, capable of handling reels up to 17 inches in size. This versatility makes them ideal for various applications, from small batches to large-scale productions.

Advanced Imaging and Core Technology

- Equipped with cutting-edge core technology and a high-resolution image system, ELT’s SMT X-ray Parts Counters deliver unparalleled image clarity. This modern imaging system ensures that every component is counted accurately, providing you with reliable results every time.

Intelligent Algorithm for Superior Accuracy

- ELT’s SMT features an intelligent algorithm method that ensures precise counting across a wide range of components and reels. With an impressive repeat accuracy of 99.99%, this advanced system is both practical and time-saving, allowing you to maintain high standards of quality control.

Customization Options to Meet Your Requirements

- We understand that every manufacturing process has unique requirements. That’s why we offer customization options for ELT’s SMT X-ray Component Counters. Provide us with your specific needs, and we will tailor the solution to meet your preferences, ensuring you get the most out of your investment.

Features of ELT’s SMT X-Ray Reel Counters

- Higher Resolutions: Microfocus X-ray sources enable sub-micron resolution imaging to detect microscopic defects.

- Faster Line Scan Rates: High-speed line scan cameras reach over 200mm/second conveyor movement for rapid inspection.

- Integrated 3D Inspection: Incorporating 3D X-ray imaging for complete board visualization.

- AI-Enabled Defect Recognition: Machine learning automates analysis and defect identification without operator input.

- Large Panel Inspection: Development of larger conveyors and scanning areas to handle PCB panels over 2×2 feet.

- Dual Angle Inspection: Scanning boards from multiple angles for more complete inspection.

- Inline Integration: X-ray systems integrated into manufacturing lines for live in-process quality control.

- Cloud-Based Imaging: Uploading scanned images to the cloud for remote analysis and data analytics.

- Virtual Reality Visualization: Viewing and manipulating scanned 3D board data in VR for immersive inspection.

- Automated Reporting Tools: Systems that generate inspection reports, trends, and analysis without extensive manual work.

These trends enhance X-ray inspection’s resolution, speed, automation, and integration into manufacturing, maximizing quality and minimizing defects.

X-RAY TECH INSIDER

INFO GUIDE

A Guide to: How to choose the perfect x-ray solution for your industry in 2024

U̶S̶$̶2̶4̶.̶9̶9̶

U̶S̶$̶2̶4̶.̶9̶9̶

Let’s collaborate!

Whether you’re looking for cutting-edge X-ray solutions or expert technical support, our team is here to help. Contact us today to discuss your requirements and discover how ELT can partner with you for success.