Innovative X-ray Inspections for Batteries

Revolutionize Your Inspections with the MirXT-160

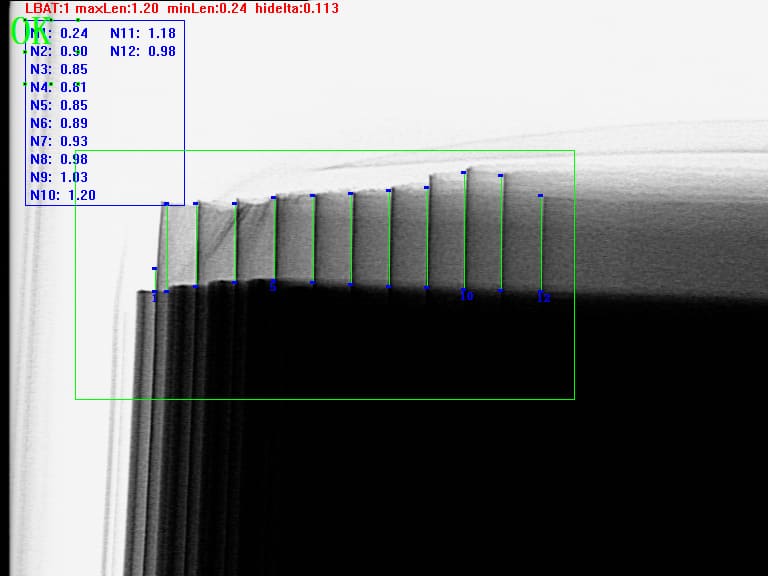

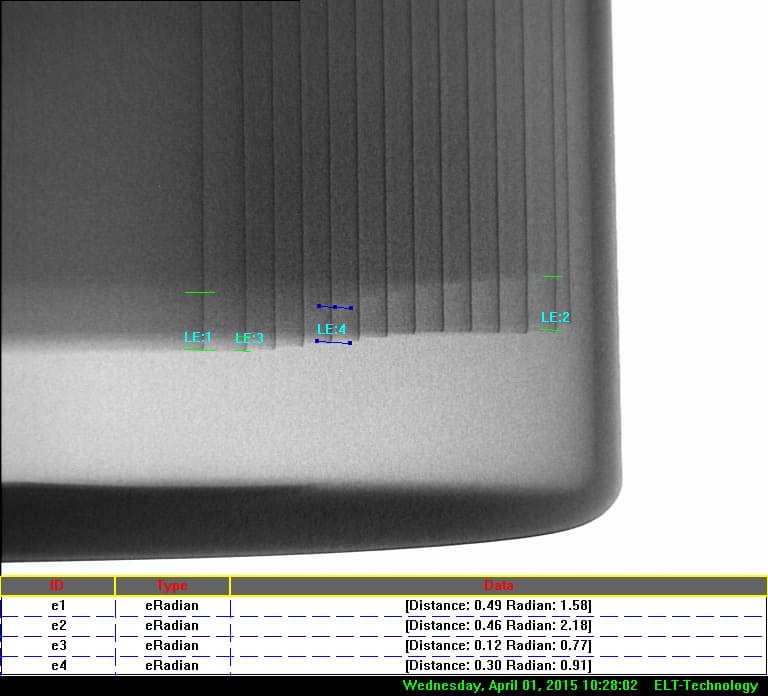

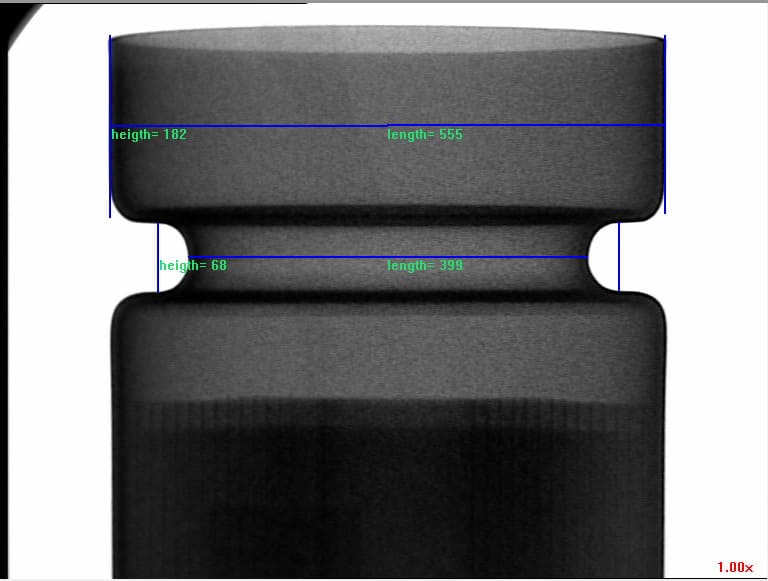

Accurate Defect Detection and Performance Monitoring

Unbeatable Offer Challenge!

Unbeatable Offer Challenge!

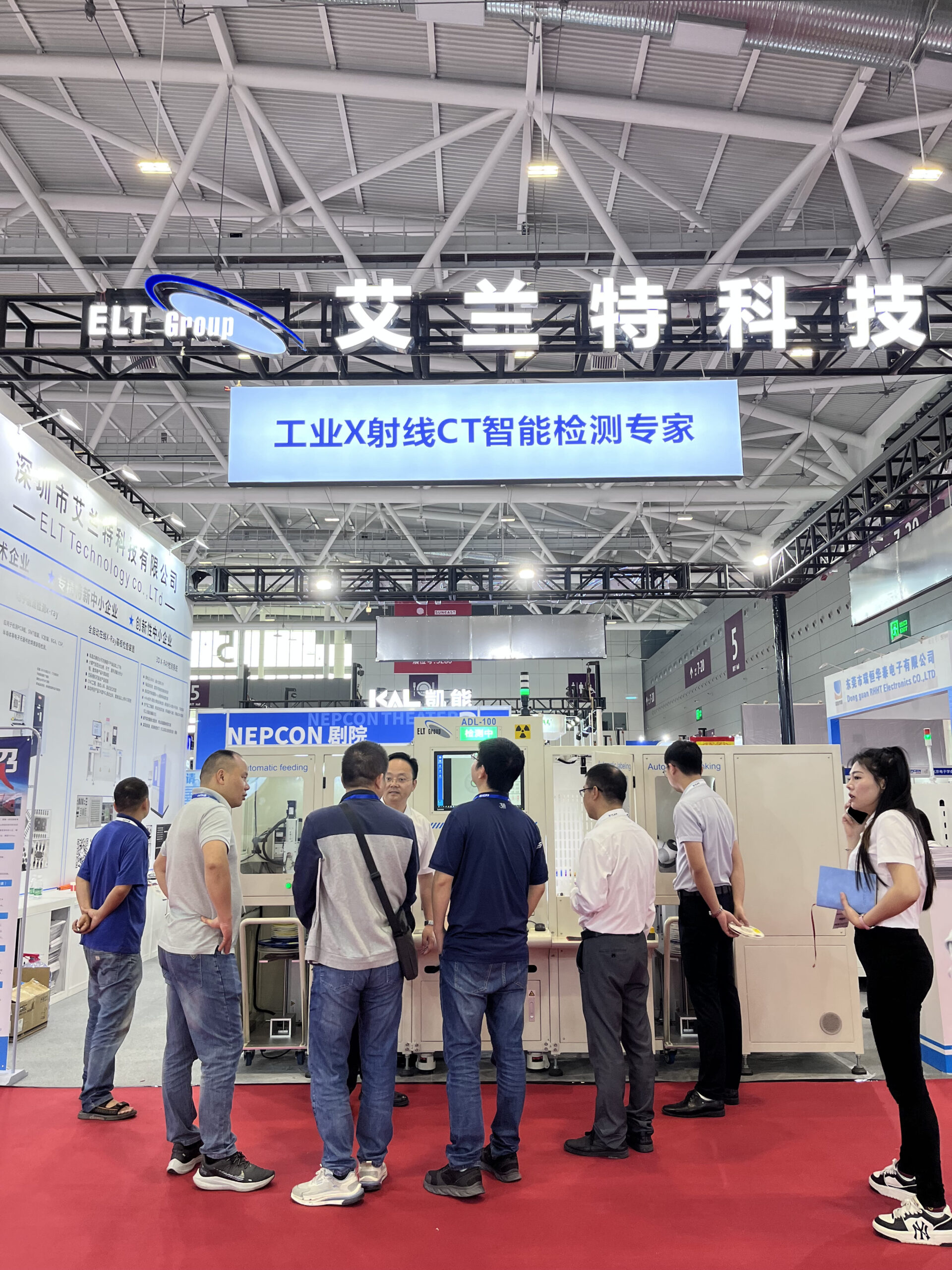

ELT’s Battery X-Ray Machines

Specs Overview

Product-Line

Application Product Samples

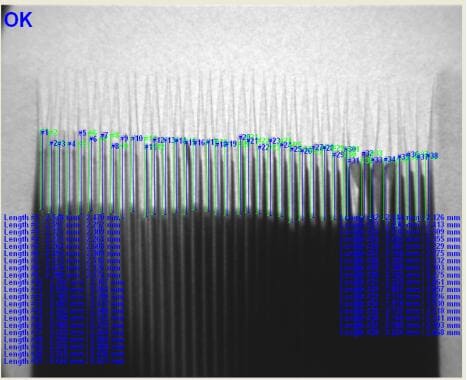

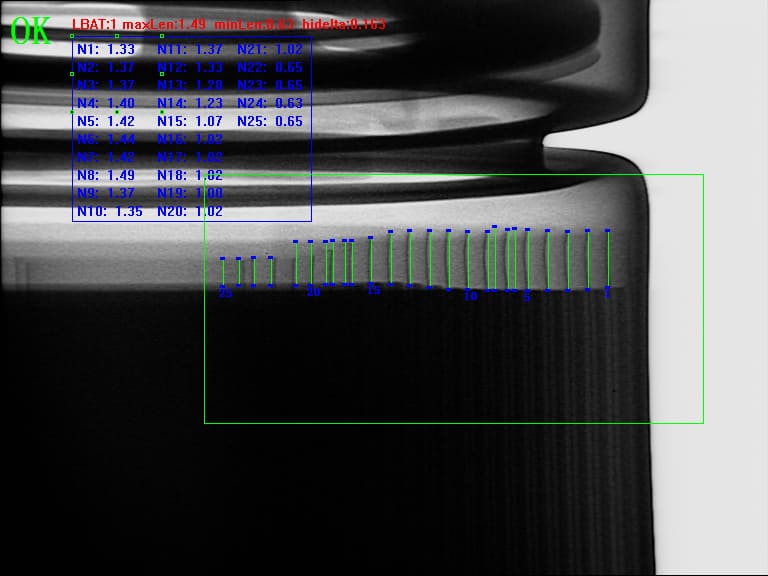

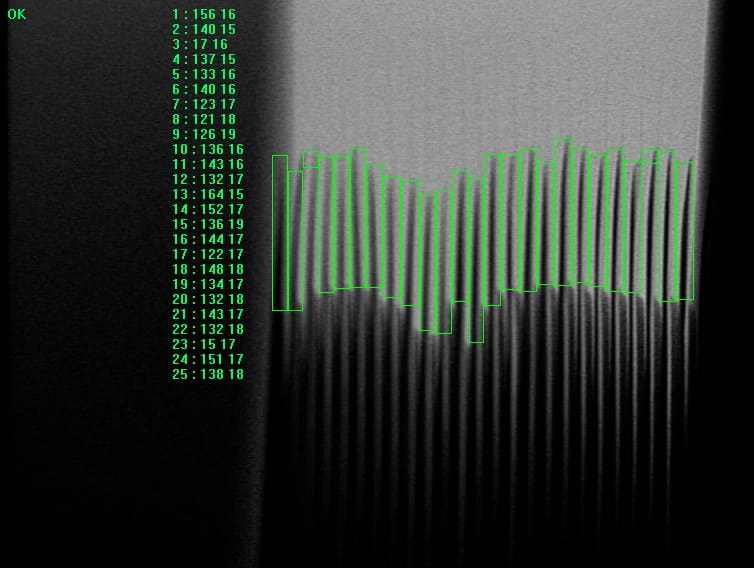

X-Ray Inspection Images

Contact

+86-18929317246

[email protected]

Our location

3rd floor, Building 3, Yuheng Industrial Park No. 2 (Guangshen Highway), Tantou Community, Songgang, Baoan District, Shenzhen, Guangdong, P. R. China.

Social profiles

Let’s collaborate!

Whether you’re looking for cutting-edge X-ray solutions or expert technical support, our team is here to help. Contact us today to discuss your requirements and discover how ELT can partner with you for success.