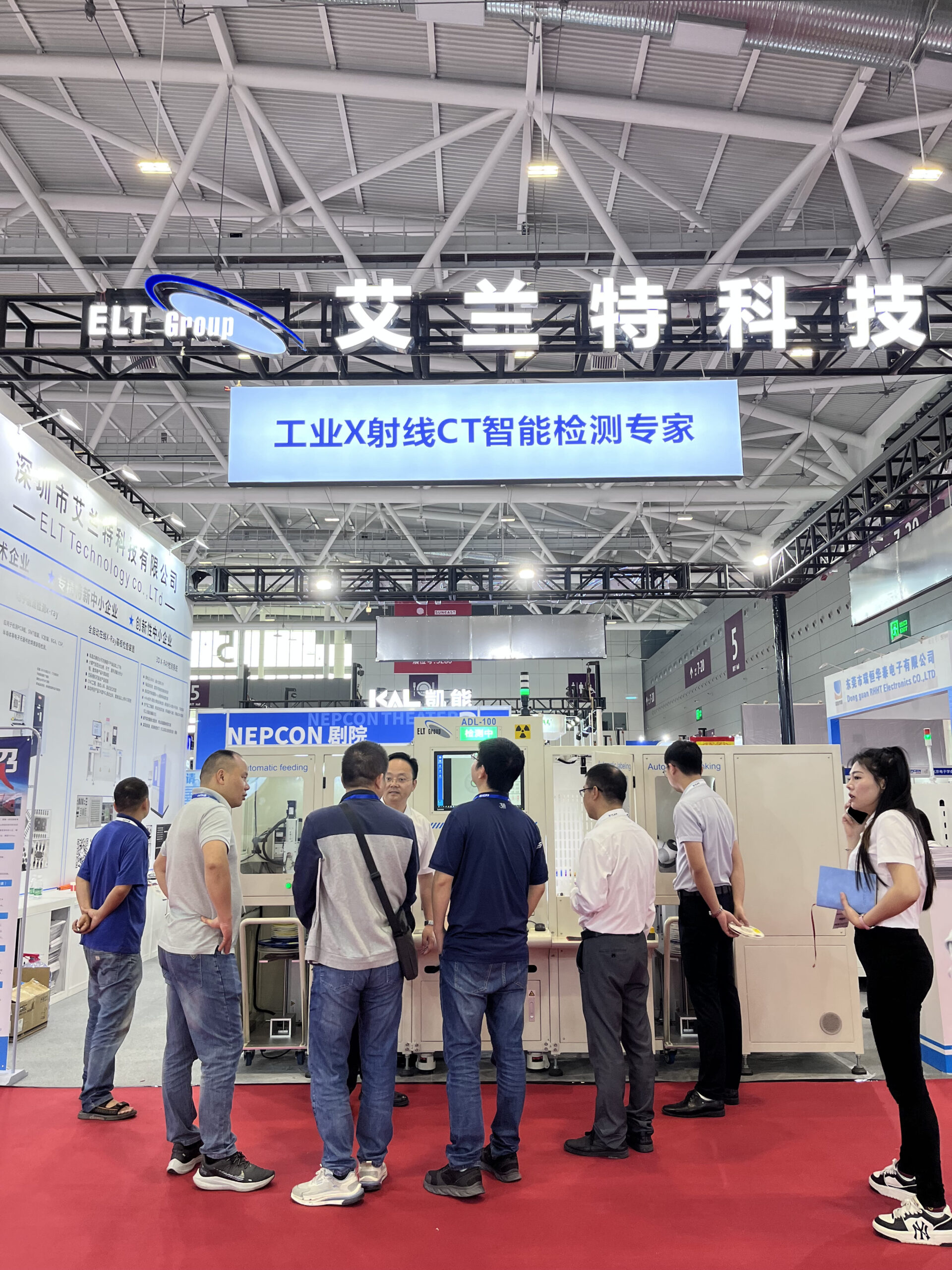

Discover the Future of Casting X-Ray Inspections with ELT Technology

Revolutionize Your Inspections with the MirXT-160

Unparalleled Precision and Reliability in Casting X-Ray Inspections

ELT’s Casting X-Ray Machines

Experience and Capabilities

- Customized casting X-ray solutions to meet diverse industry needs

- Advanced casting X-ray technology

- Comprehensive inspection capabilities

- Ensures structural integrity and quality performance

- Innovative solutions tailored to specific requirements

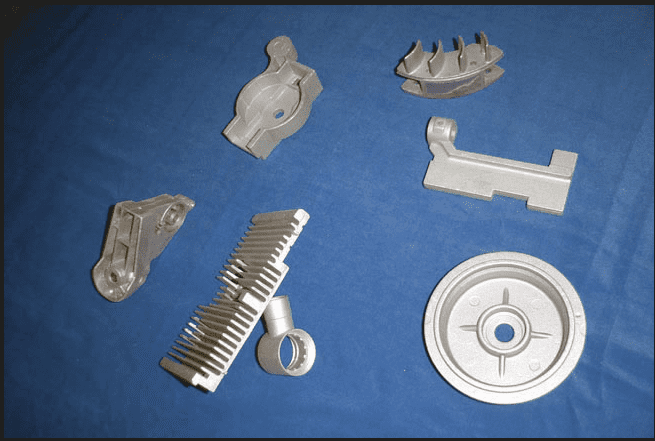

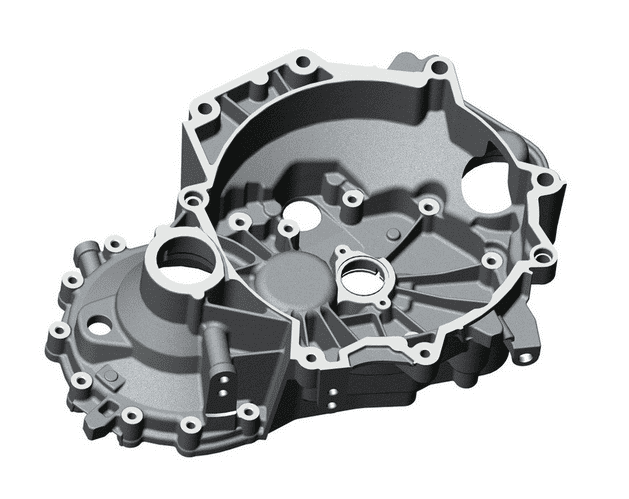

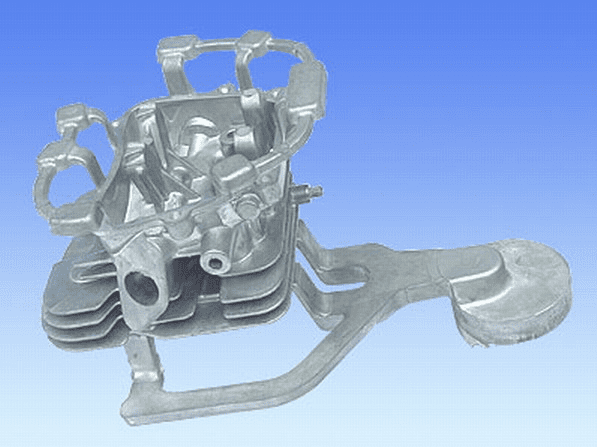

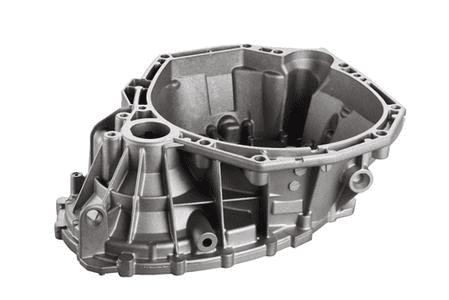

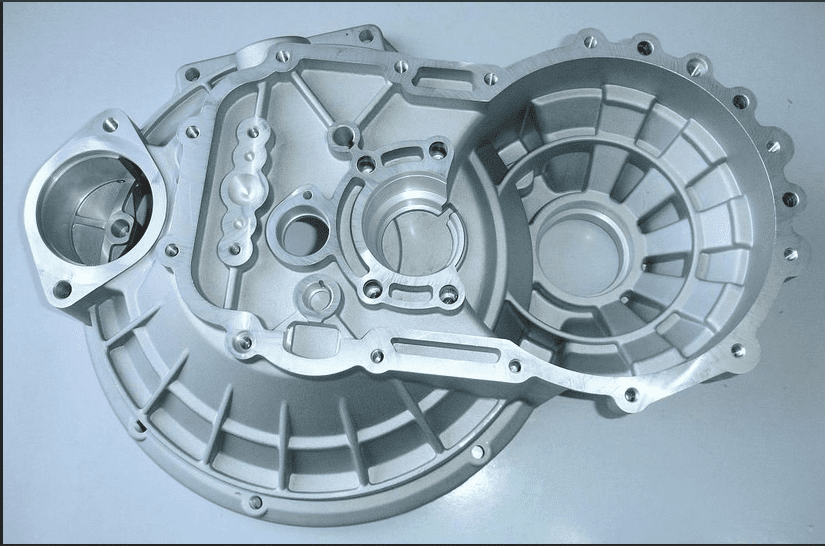

Industries Used-in

- Non-destructive testing of automobile parts

- Aluminum and iron castings

- Hardware products

- Tire wheels

- Pressure vessels

- Refractory materials

- Boiler pipes

- Other industrial and scientific research fields

Use Applications

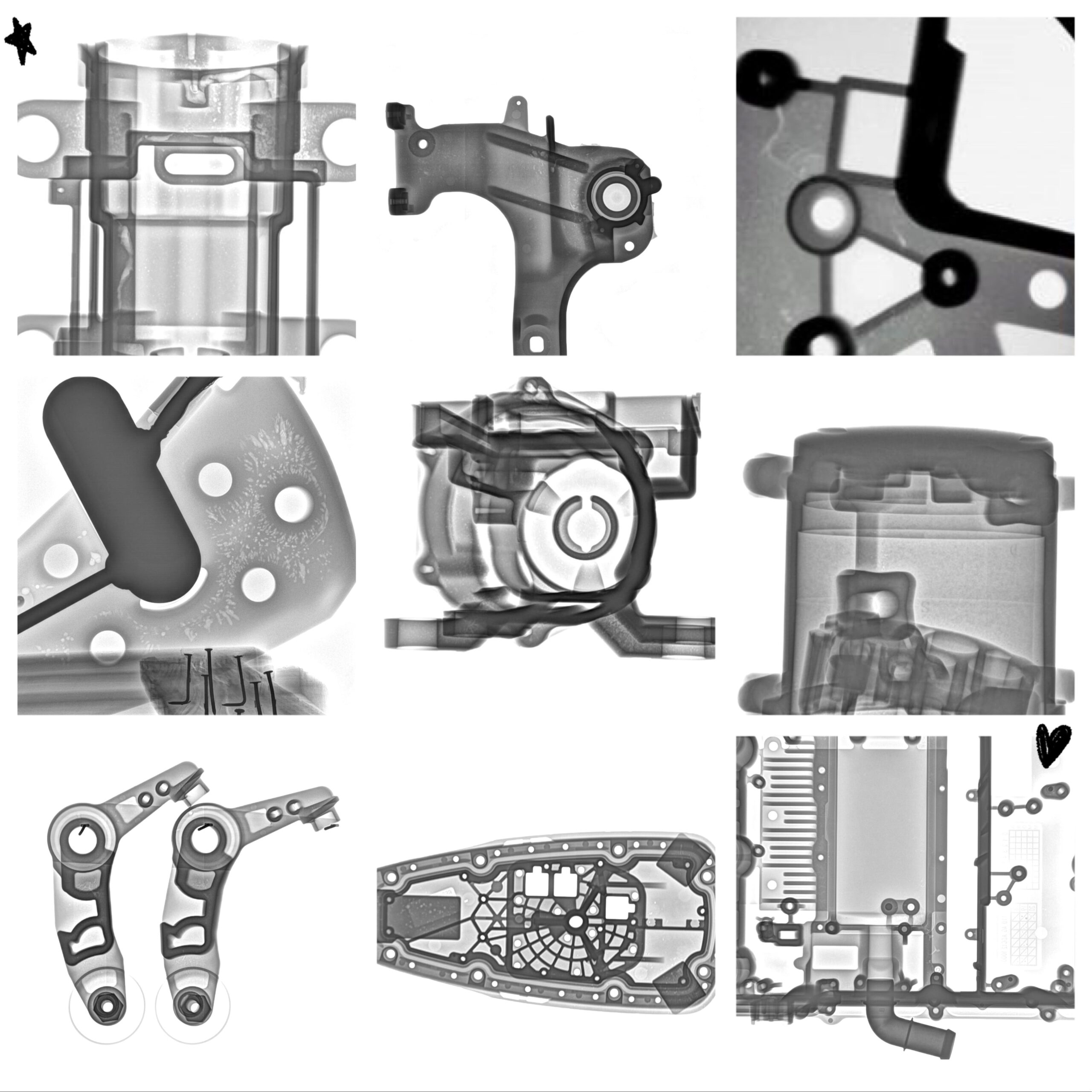

- Comprehensive inspection and testing of cast components

- Ensures structural integrity and quality performance

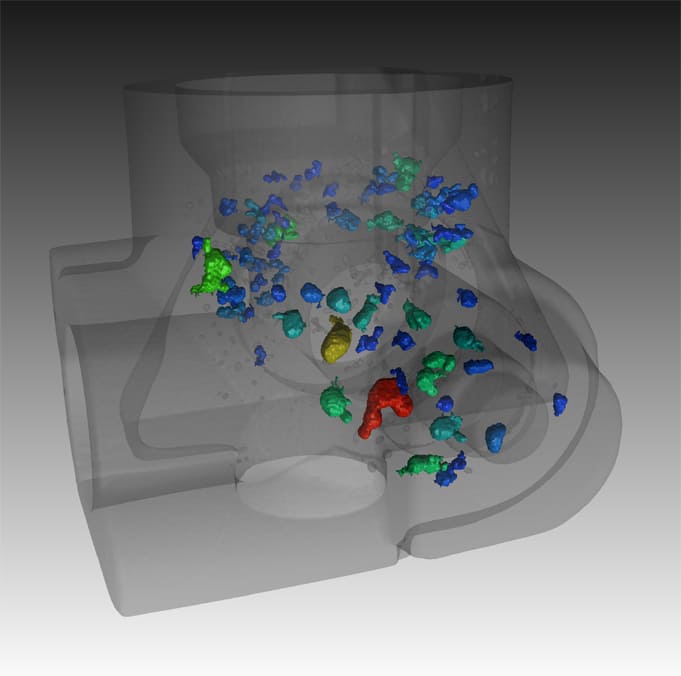

- Detection of internal defects in casting materials

- Verification of dimensional accuracy and consistency

Unbeatable Offer Challenge!

Unbeatable Offer Challenge!

Tell us your needs,

Get the UNMATCHED Quote on X-ray Solutions in the Industry!

– guaranteed to meet your exact needs and budget!

ELT’s Battery X-Ray Machines

Specs Overview

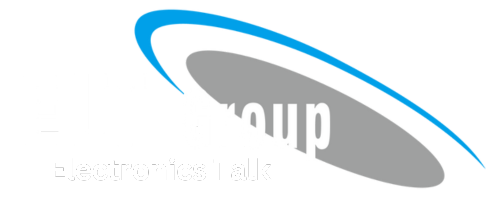

Casting X-ray Inspection | HT1000:

Discover our advanced non-destructive testing equipment designed for various lightweight flat plate products, including gold and Li castings, auto parts, plastic products, and rubber products. Engineered for precision and cost-effectiveness, our inspection solutions offer high integration and space-saving design.

Functions and Features

- Precision Inspection: Ideal for small precision casting inspections, ensuring cost-effectiveness.

- Compact Design: High integration with a compact structure, saving valuable space.

- Enhanced Detection: Features a small focus size with advanced software HDR processing for superior image quality.

Detailed Specification

| X-Ray Tube | Tube Style | Sealed Tube |

| Tube Voltage | 160KV | |

| Tube Current | 2.5mA | |

| Optical Tube Power | 400W | |

| Detail Resolution | 0.4-0.8mm | |

| Cooling Mode | Air Cooling | |

| Plat Panel Detector | Effective Imaging Area | 432mm*432mm |

| Pixel size | 2816×2816mm | |

| A/D change | 16Bit | |

| Sample Table | Axis X | 400mm |

| Axis Y | 400mm | |

| Sample Table | 500*500mm | |

| Effective Visual Range | 400*400mm | |

| Software and Image Processing Capabilities | Measuring Function | The bubble crack of the test sample was determined by software |

| Software Processing Power | Image inversion, sharpening, histogram, binarization for better analysis

X-RAY picture |

|

| Image Enhancement | Automatic image enhancement, Image reverse color, Image edge smoothing, Texture | |

| Software Protection Capability | When the machine is unmanned, the X-ray is automatically disconnected after 20 minutes, thus extending the life of the X-ray tube | |

| Radiation Safety | The machine surface is less than 1usv/h | <1usv/h |

| Safety door automatic interlock protection function | when the X-ray is turned on, the safety door automatically locks for protection | |

| X-Ray Subject | Size | L1005mm*W1180mm*H1625mm |

| Weight | about 1400kg | |

| Power | Power Supply Mode | AC110-230VAC,50/60Hz |

Casting X-ray Inspection | HT2000D:

Experience state-of-the-art detection technology with our equipment designed for small and medium-sized products such as metal castings, welding parts, hardware products, plastic products, rubber products, and ceramic bodies. This advanced system offers precise, intelligent, and automated inspection capabilities.

Functions and Features

- Comprehensive Detection: Automatic detection system with intelligent discrimination, automatic analysis, and report generation.

- High Efficiency: Fast and smooth motion performance ensures high detection efficiency.

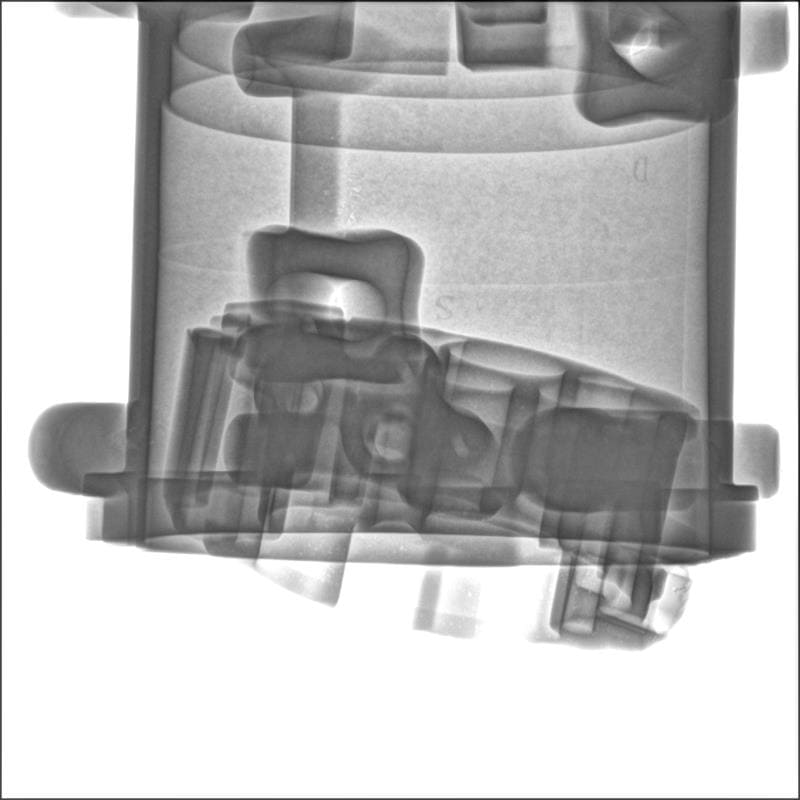

- Enhanced Imaging: Real-time dynamic imaging with HDR image enhancement software for superior clarity.

- 360° Inspection: Platform rotation for no dead angle detection.

- Versatile Applicability: Capable of detecting various workpieces with a wide range of applicability.

- Advanced Defect Recognition: Equipped with Automatic Defect Recognition (ADR) function for enhanced accuracy.

Detailed Specification

| X–Ray Tube | Tube Style | Sealed Tube |

| Tube Voltage | 160KV | |

| Tube Current | 2.5mA | |

| Optical Tube | 400W | |

| Details Resolution | 0.4mm | |

| Cooling Mode | Air Cooling | |

| Flat Panel Detector | Effective Area | 157mm*157mm |

| Pixel Size | 154um | |

| A/D Change | 16Bit | |

| Sample Table | Axis Z | 650mm |

| Axis X | 400mm | |

| Axis Y | 440mm | |

| Axis U | ±35°tilt | |

| Axis R | Horizontal 360° Rotation | |

| Maximum Bearing Capacity | 30KG | |

| Software and Image Processing Capabilities | Measuring function | The bubble crack of the test sample was determined by software. |

| Software processing Power | Image Inversion, Sharpening, Histogram, Binarization for better analysis of X-RAY images | |

| Image Enhancement | Automatic Image Enhancement, Image Reverse color, Image Edge Smoothing, Texture | |

| Software Protection Capability | When the Machine is Unmanned, the X-Ray is automatically disconnected after 20 minutes, thus extending the life of the X-ray tube | |

| Radiation safety | The machine surface is less than 1usv/h | <1usv/h |

| Safety door automatic interlock protection function | When the X-ray is turned on, the safety door automatically locks for protection | |

| computer | Brand | Advantech |

| System | WIN10 | |

| CPU | I5 | |

| X-Ray subject | Size | Host machine:L1465mm*W1165mm*H1923mm

Operating table:L950mm*W870mm*1359mm |

| Weight | About 2000kg | |

| Power | Power supply mode | AC110-230VAC,50/60Hz |

Casting X-ray Inspection | HT5000:

Explore our versatile non-destructive testing equipment, ideal for auto parts, casting, welds, aerospace components, and related industries. Designed to meet the diverse inspection needs of small to medium workpieces, thin-walled light workpieces, and thick gray cast iron, this equipment ensures precise and reliable detection of various defects in tires, wheels, and other castings, maintaining product quality and safety.

Functions and Features

- Wide Application Range: Suitable for a variety of industries including auto parts, castings, welds, and aerospace.

- Comprehensive Inspection: Capable of inspecting small, medium, and thin-walled light workpieces, as well as thick gray cast iron.

- High Detection Accuracy: Quickly and accurately detects defects in tires, wheels, and other castings.

- Efficient Performance: Fast and smooth motion performance with high detection efficiency.

- 360° Coverage: Tilted detector and X-ray tube with 360° platform rotation for no dead angle detection.

- Large Detection Space: Accommodates large objects with ample internal detection space.

- Enhanced Imaging: Real-time dynamic imaging with HDR image enhancement software for clear, detailed results.

Detailed Specification

| X–Ray Tube | Tube Style | Sealed Tube |

| Tube Voltage | 160KV | |

| Tube Current | 2.5mA | |

| Optical Tube Power | 400W | |

| Detail Resolution | 0.4mm | |

| Cooling Mode | Air Cooling | |

| X–Ray | X-Ray Rotation Angle | Coaxial ±45˚ tilt is possible |

| FlatPanel Detector | Effective Area | 432mm*432mm |

| Pixel Size | 2816×2816 | |

| A/D Change | 16Bit | |

| Sample Table | Axis Z | 800mm |

| Axis X | 500mm | |

| Axis Y | 500mm | |

| Axis R | Horizontal 360° rotation | |

| Maximum Bearing Capacity | Maximum load 100KG | |

| Software and Image Processing Capabilities | Measuring Function | The bubble crack of the test sample was determined by software |

| Software Processing power | Image inversion, Sharpening, Histogram,Binarization for better analysis of X-RAY images | |

| Image Enhancement | Automatic image enhancement, image reverse color, image edge smoothing, texture | |

| Software Protection Capability | When the machine is unmanned, the X-ray is automatically disconnected after 20 minutes, thus extending the life of the X-ray tube | |

| Radiation Safety | Whole Machine Surface less than 1usv/h | <1usv/h |

| Safety Door Automatic Interlock Protection Function | When the X-ray is turned on, the safety door automatically locks for protection | |

| Radiation Door | Manual button on and off | |

| Computer | Brand | Advantech |

| System | WIN10 | |

| CPU | I5 | |

| X-Ray subject | Size | L1822mm*W1535mm*H1929mm |

| Weight | about 4500kg | |

| Power | Power Supply | AC110-230VAC,50/60Hz |

Casting X-ray Inspection | HT5000C:

Introducing our advanced on-line X-ray inspection machine, specifically designed for the automatic inspection of auto parts. This state-of-the-art system leverages image detection technology and X-ray perspective to convert visible light images, enabling high-definition imaging, automatic positioning, and precise image processing.

Functions and Features

- Automatic Operation: Features automatic feeding, positioning, measurement, judgment, and storage of product images and measurement data.

- High-Definition Imaging: Uses a dry Meg network to input image information of the workpiece into the PC host for high-definition imaging and processing.

- Defect Detection: Automatically calculates the area and proportion of defects like pores and cracks to determine product qualification.

- Stable and Accurate: Provides stable, correct, and consistent test results.

- User-Friendly: Simple operation with the ability to set testing standards for new products within 30 minutes.

- Customizable Results: Test results can be freely set, including save path, picture format, and qualified or unqualified pictures.

Detailed Specification

| X Tube | Tube Style | Sealed Tube |

| Tube Voltage | 130KV | |

| Detail Resolution | 3um | |

| Cooling mode | Air Cooling | |

| Geometry Magnification Time | 320X | |

| Flat Panel Detector | Effective Area | 157mm*157mm |

| Pixel Size | 154um | |

| A/D Change | 16Bit | |

| Sample Table | Axis X | 400mm |

| Axis Y | 300mm | |

| Axis R | 60° | |

| Maximum bearing capacity | 20KG | |

| Radiation safety | The Machine Surface is less than 1usv/h | <1usv/h |

| Safety door automatic interlock protection function | When the X-ray is turned on, the safety door automatically locks for protection | |

| Radiation door | Manual Button On and Off | |

| X-Ray subject | Size | L1450mm*W1400mm*H1600mm |

| Weight | about 2000kg | |

| Power | Power Supply | AC220VAC,50/60Hz |

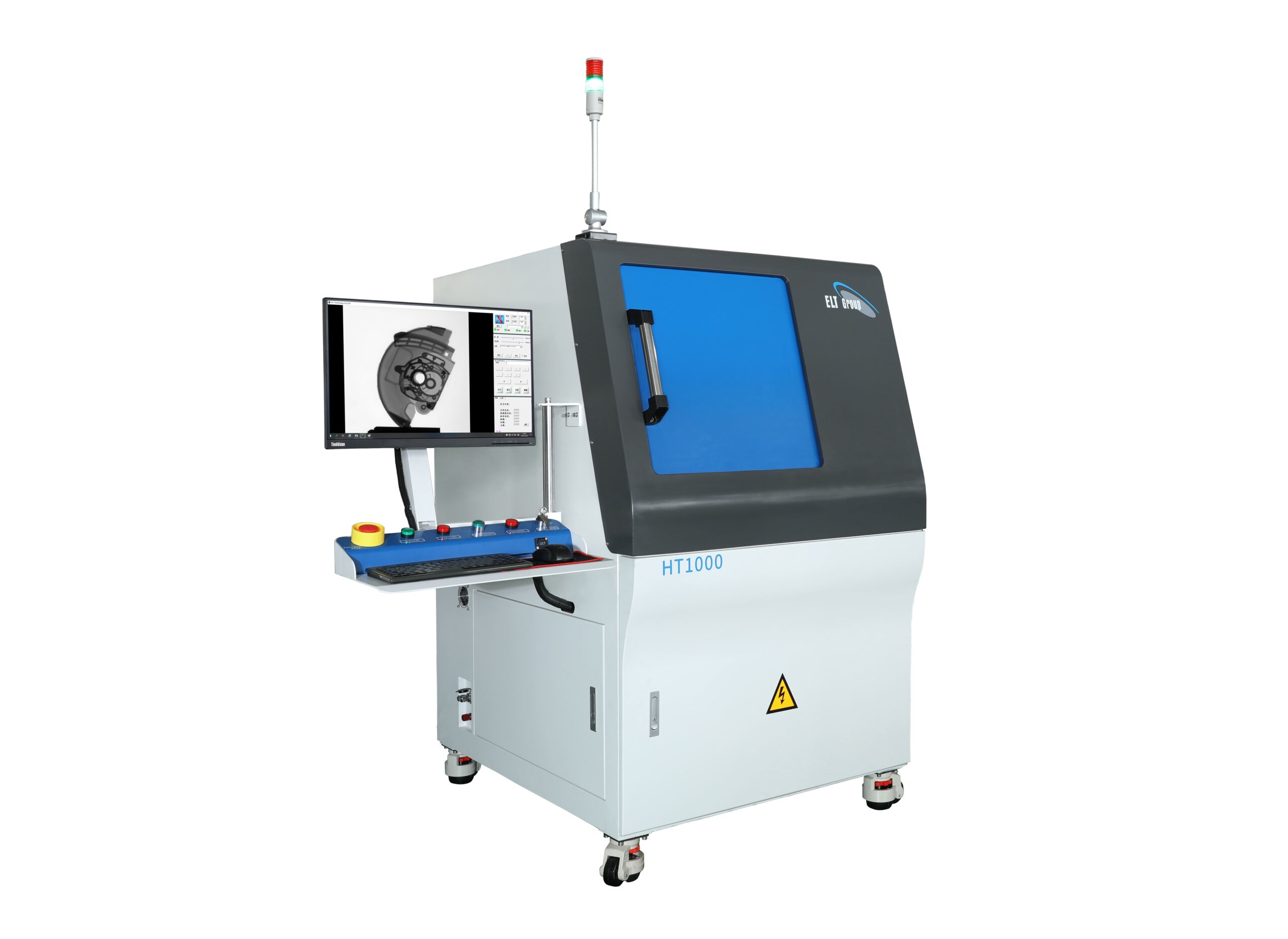

Casting X-ray Inspection | HT100:

Discover our cutting-edge non-destructive testing equipment designed for detecting bubbles, pores, and foreign bodies in automobile steering wheels and various small castings. This advanced system ensures precise and reliable inspection to maintain high product quality and safety.

Functions and Features

- Comprehensive Defect Detection: Specially designed for identifying bubbles, pores, and foreign bodies in automotive steering wheels and small castings.

- Automatic Testing: Equipped with advanced automatic testing software to determine product quality accurately.

- 360° Multi-Angle Inspection: The workpiece on the pallet detection platform can be rotated 360°, allowing for thorough inspection from multiple angles.

Detailed Specification

| X-Ray Tube | Tube Style | Sealed Tube |

| Tube Voltage | 160KV | |

| Tube Current | 2.5mA | |

| Penetration Power | 50mm(AL) | |

| Detail Resolution | D=0.4mm | |

| Cooling Mode | Air Cooling | |

| Flat Panel Detector | Effective Area | 427mm*427mm |

| Pixel Size | 154um | |

| A/D Change | 16Bit | |

| Sample Table | Axis X | 420mm |

| Axis Y | 480mm | |

| Axis Z | 360mm | |

| Axis R | Horizontal 360° Rotation | |

| Maximum Bearing Capacity | 10KG | |

| Software and Image Processing Capabilities | Measuring Function | The bubble crack of the test sample was determined by software |

| Software Processing Power | Image Inversion, Sharpening, Histogram, Binarization for better analysis of X-RAY Images | |

| Image Enhancement | Automatic Image Enhancement, Image Reverse Color, Image Edge Smoothing, Texture | |

| Software Protection Capability | When the machine is unmanned, the X-Ray is automatically disconnected after 20 minutes, thus extending the life of the X-ray tube | |

| Radiation Safety | The machine surface is less than 1usv/h | <1usv/h |

| Safety door automatic interlock protection function | When the X-Ray is turned on, the safety door automatically locks for protection | |

| Computer | Brand | Advantech |

| System | WIN10 | |

| CPU | I5 | |

| X-Ray Subject | Size | L1285mm*W1100mm*H1745mm |

| Weight | about 1500kg | |

| Power | Power Supply Mode | AC110-230VAC,50/60Hz |

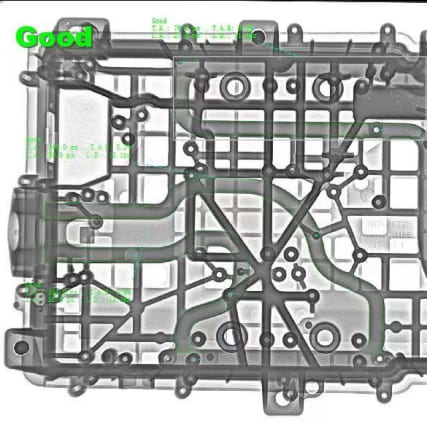

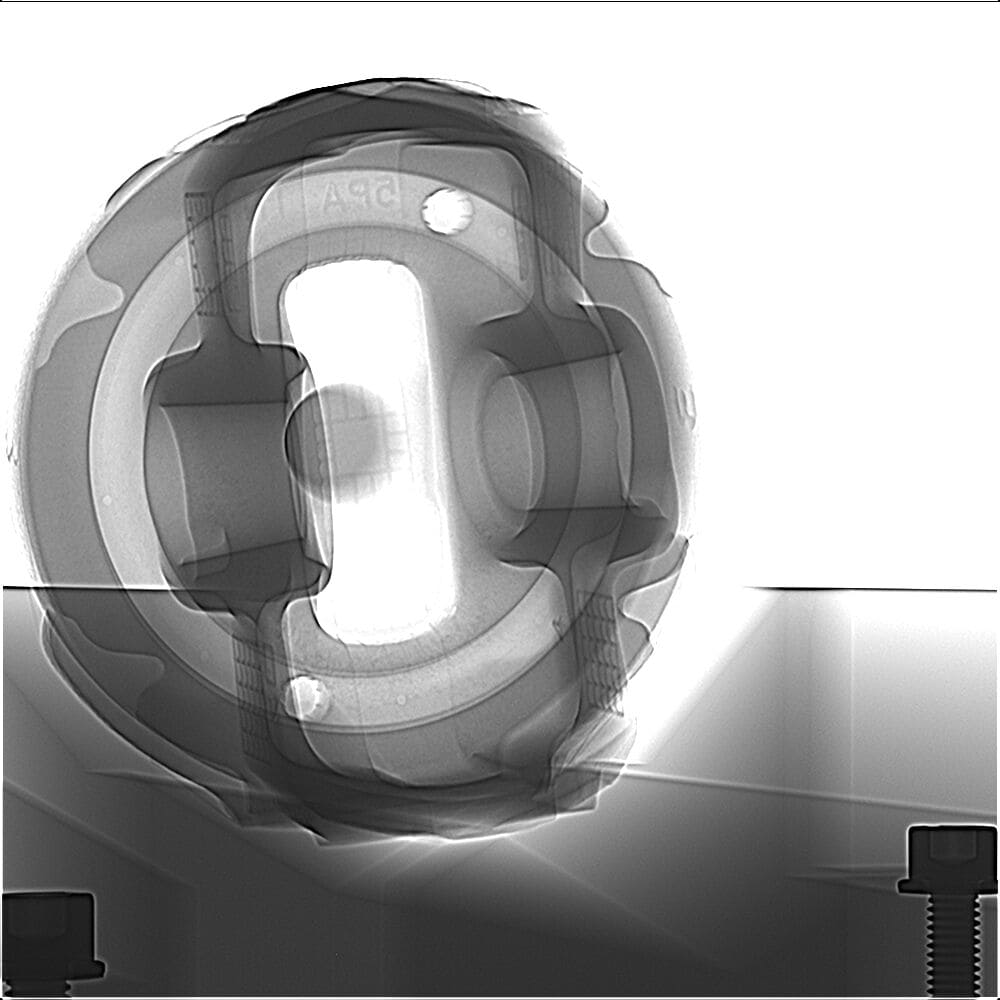

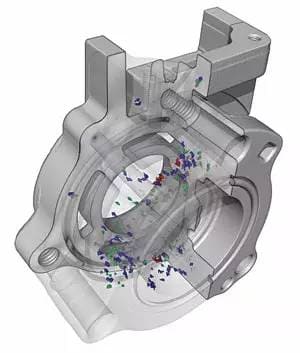

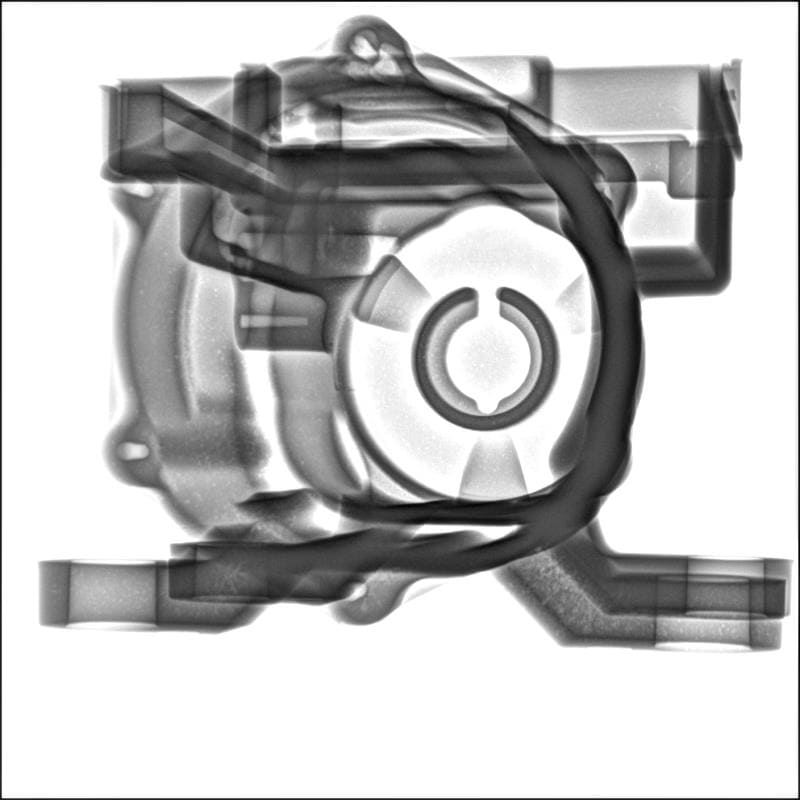

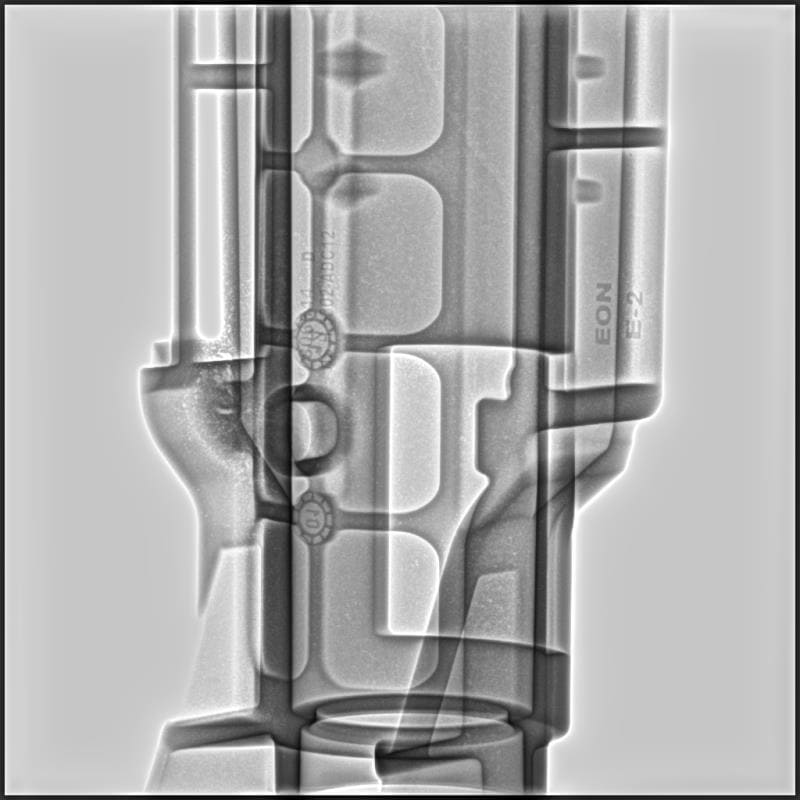

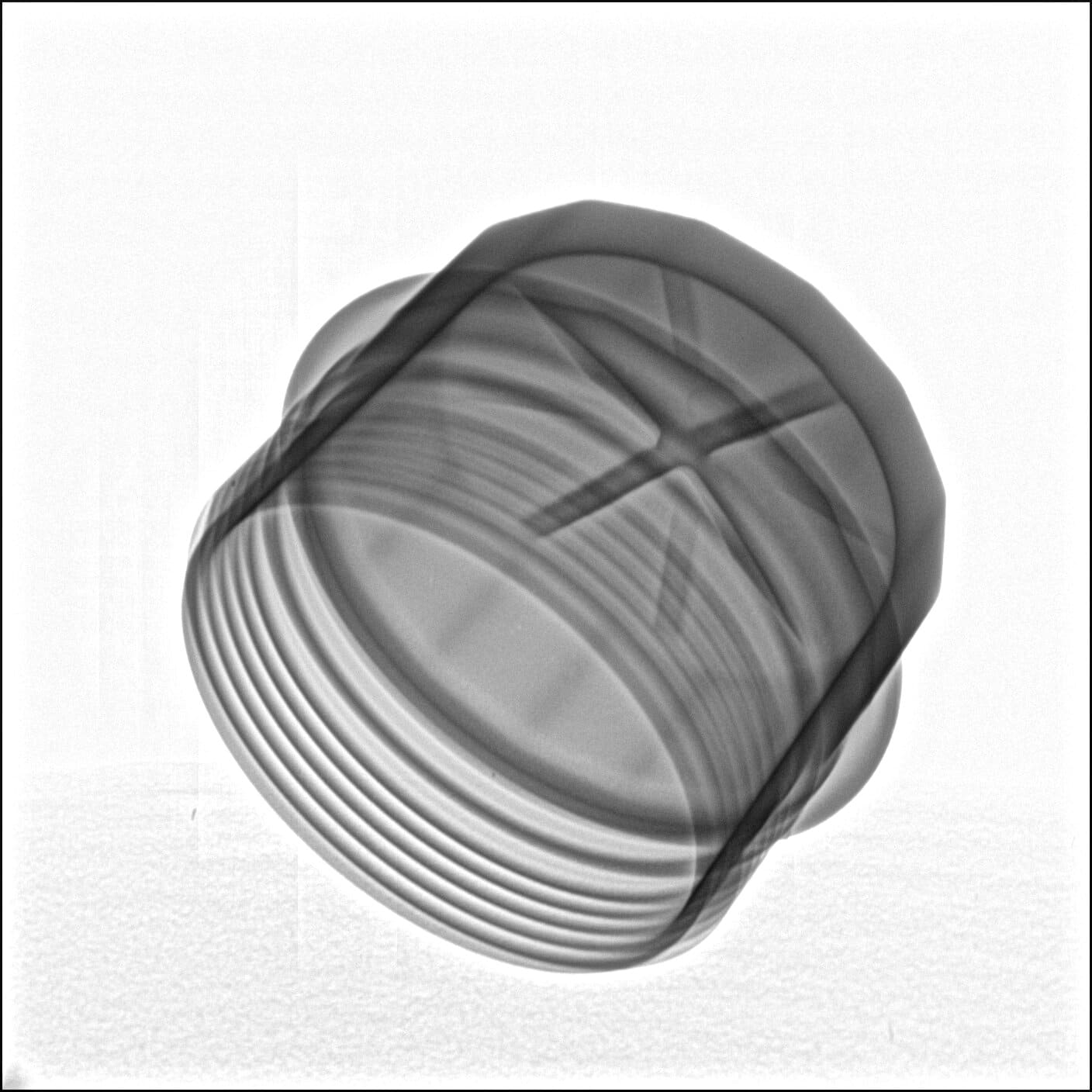

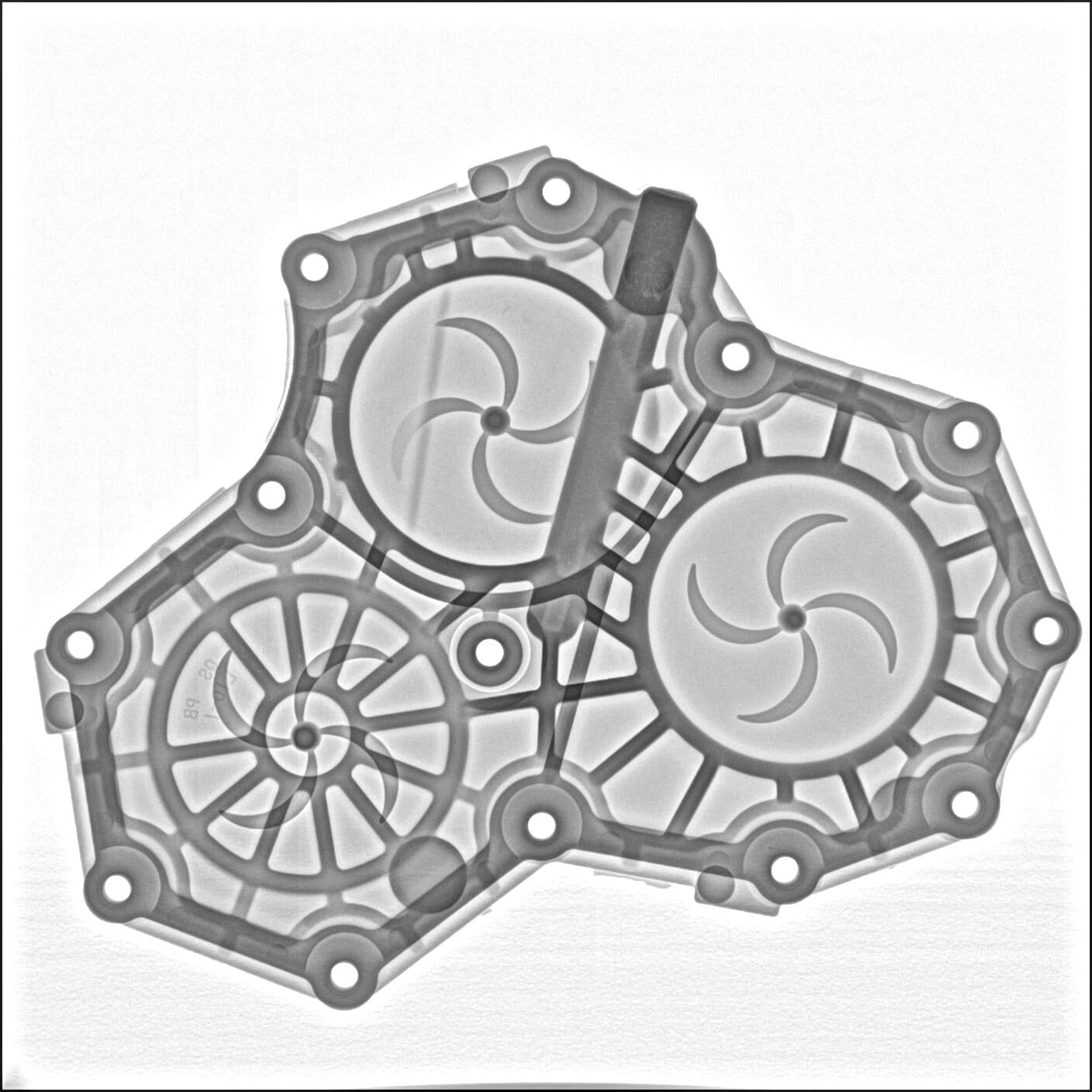

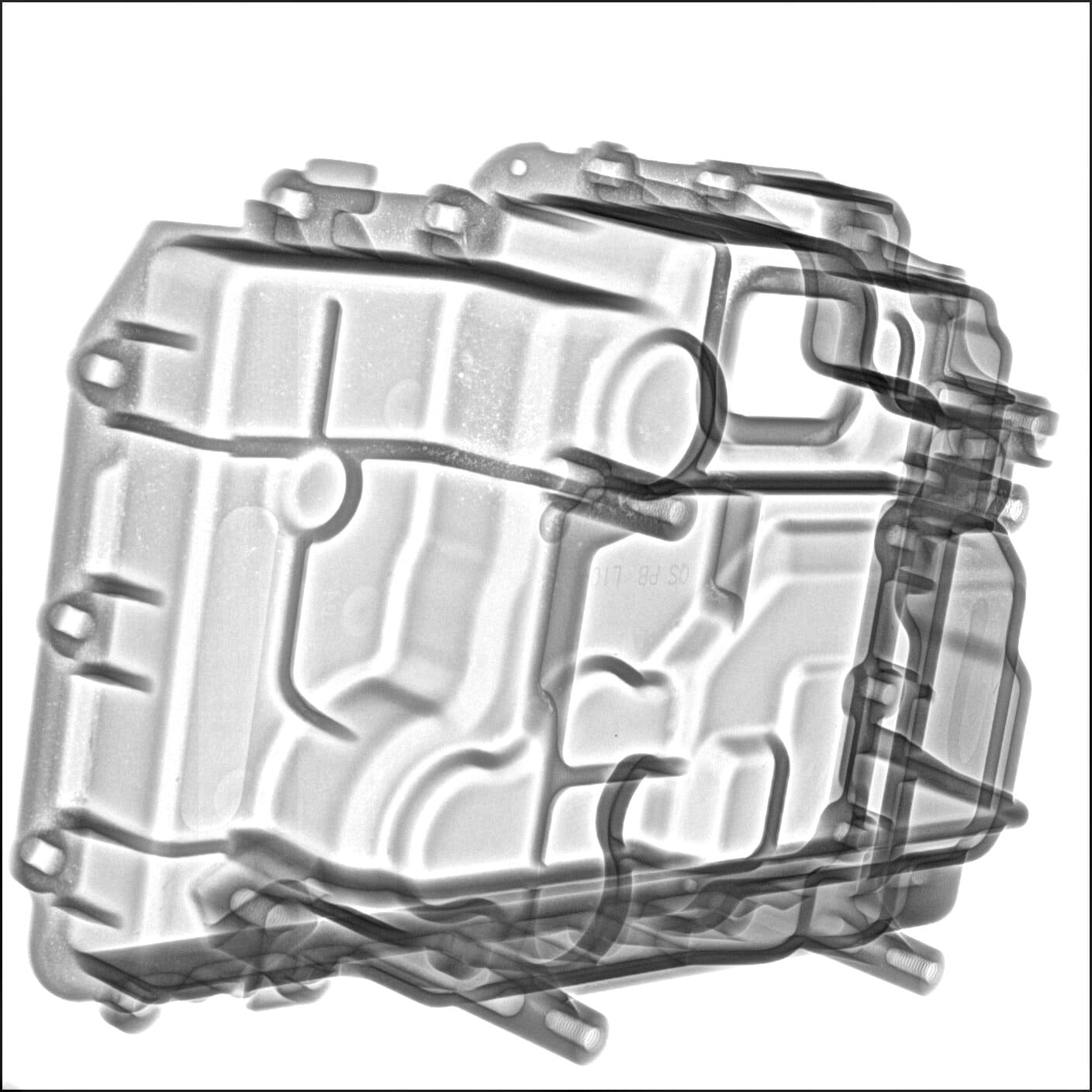

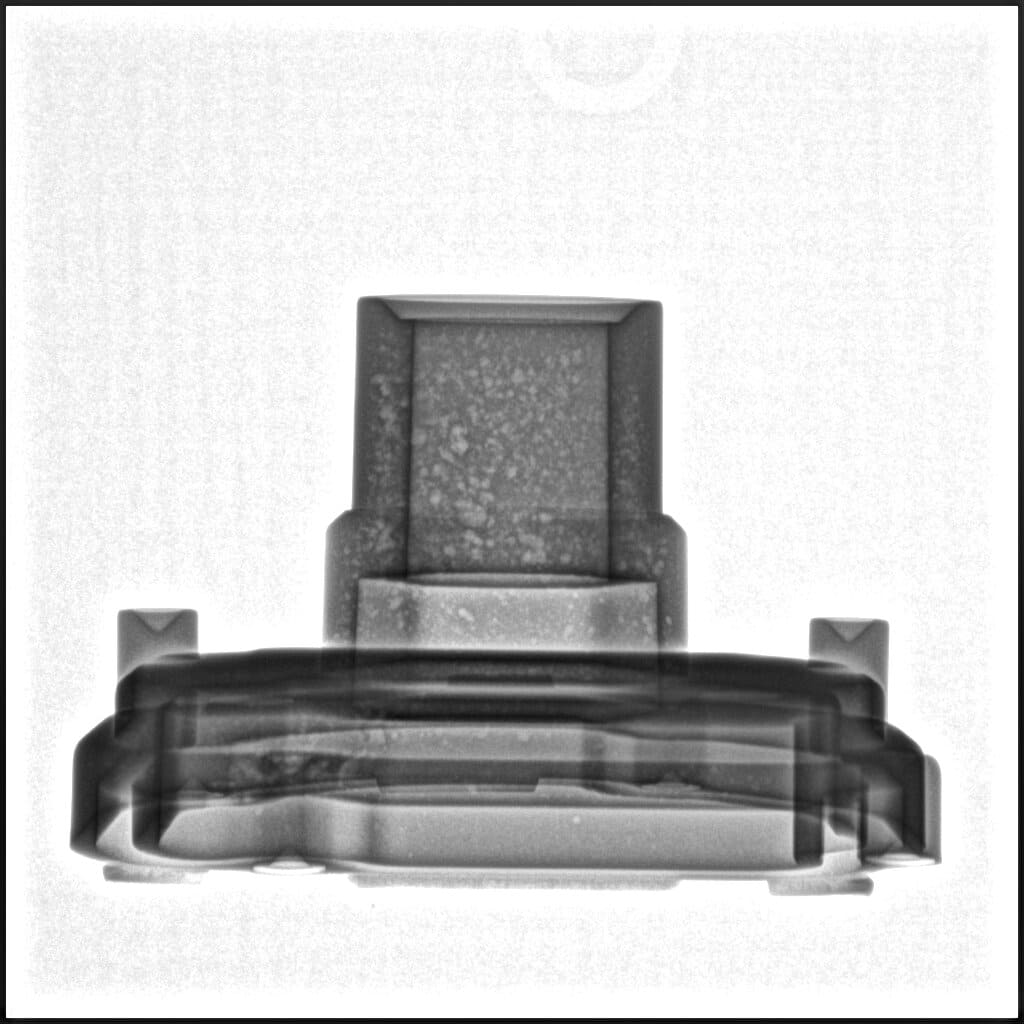

Application Product Samples

X-Ray Inspection Images

X-RAY TECH INSIDER

INFO GUIDE

A Guide to: How to choose the perfect x-ray solution for your industry in 2024

U̶S̶$̶2̶4̶.̶9̶9̶

U̶S̶$̶2̶4̶.̶9̶9̶

Contact

+86-18929317246

[email protected]

Our location

3rd floor, Building 3, Yuheng Industrial Park No. 2 (Guangshen Highway), Tantou Community, Songgang, Baoan District, Shenzhen, Guangdong, P. R. China.

Social profiles

Let’s collaborate!

Whether you’re looking for cutting-edge X-ray solutions or expert technical support, our team is here to help. Contact us today to discuss your requirements and discover how ELT can partner with you for success.