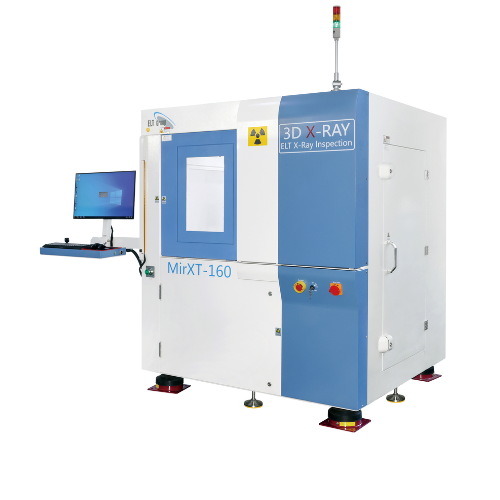

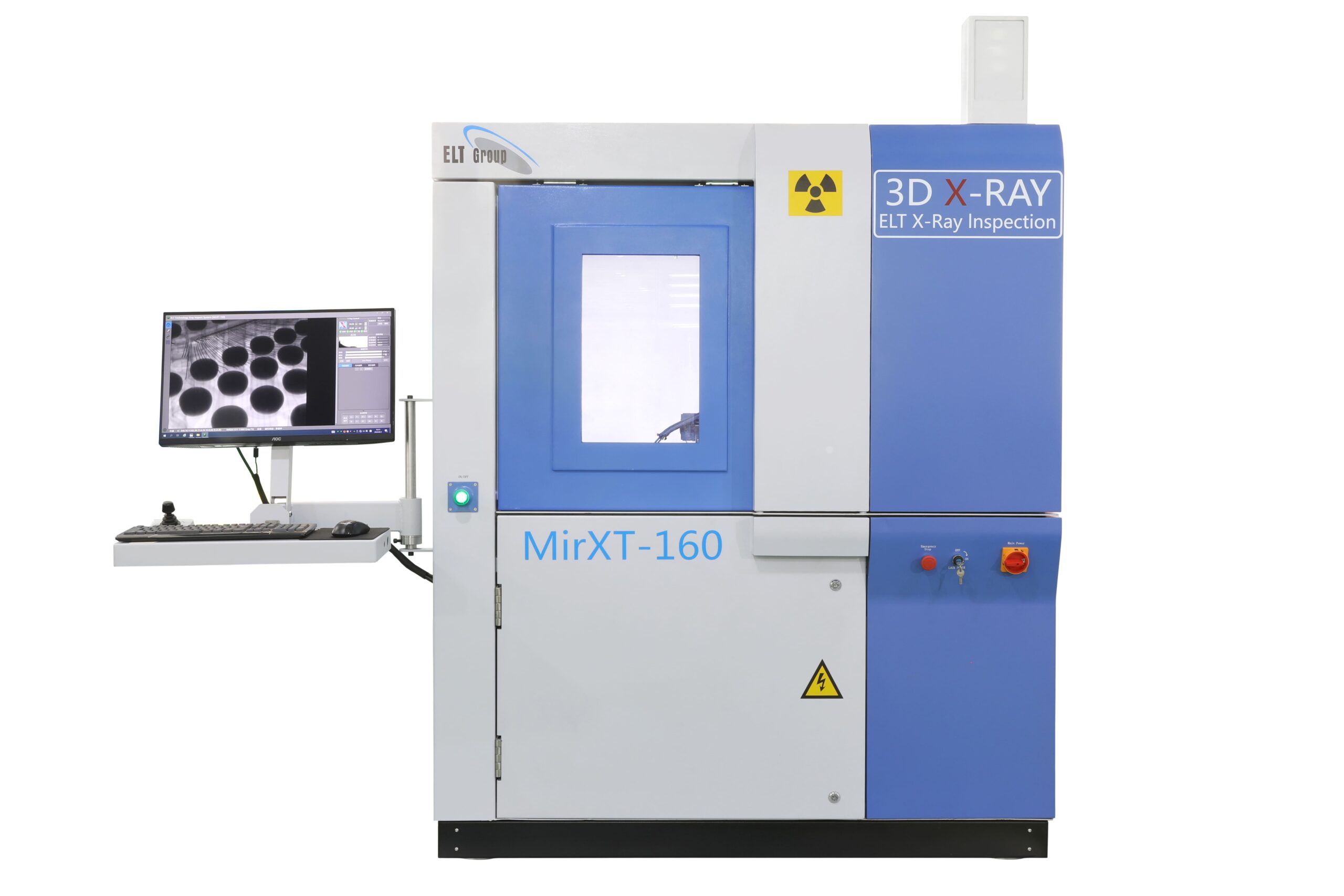

Revolutionize Your Inspections with the MirXT-160

Revolutionize Your Inspections with the MirXT-160

High-Resolution 3D CT X-Ray Imaging for Unmatched Precision and Detail

Unbeatable Offer Challenge!

Unbeatable Offer Challenge!

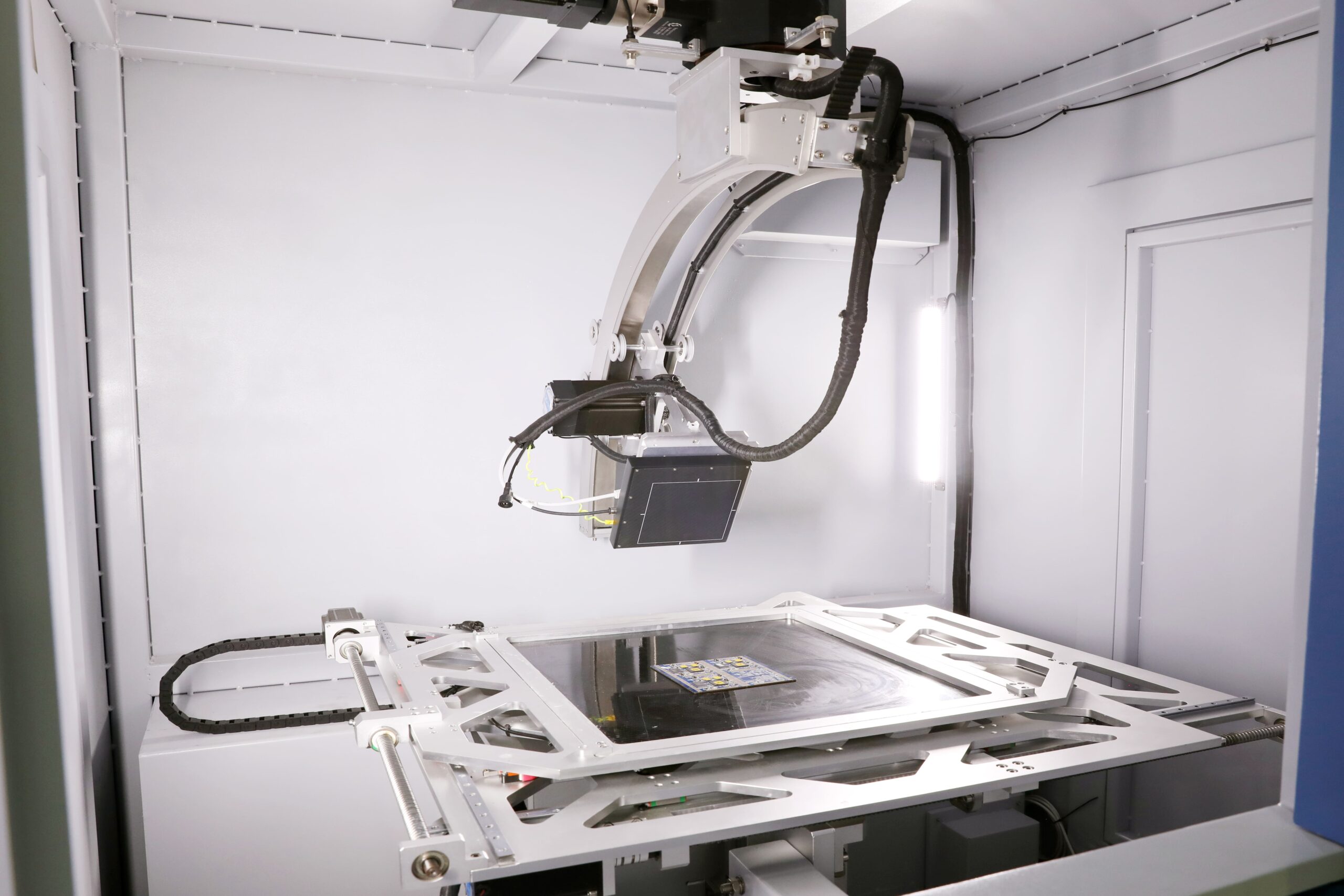

Product Pictures

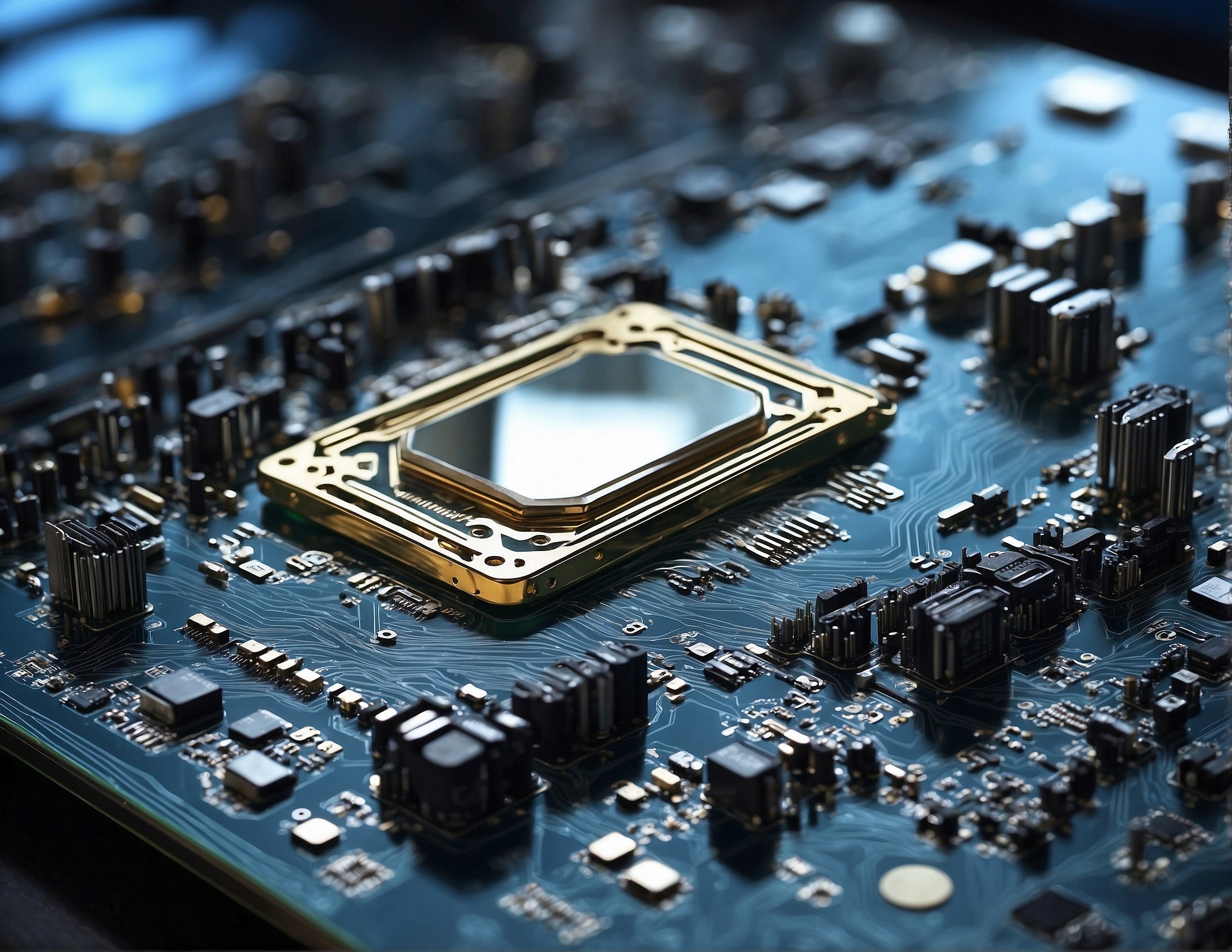

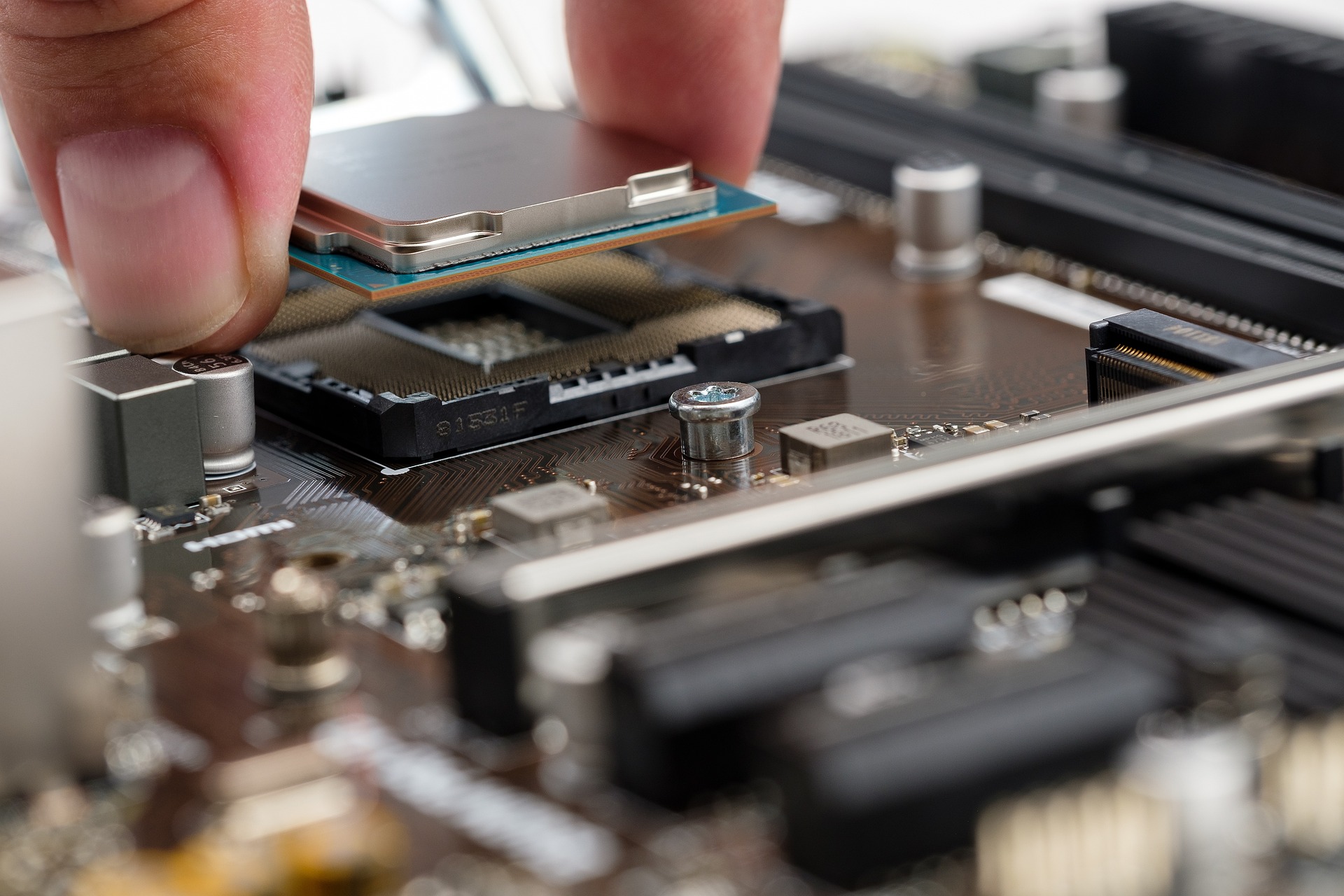

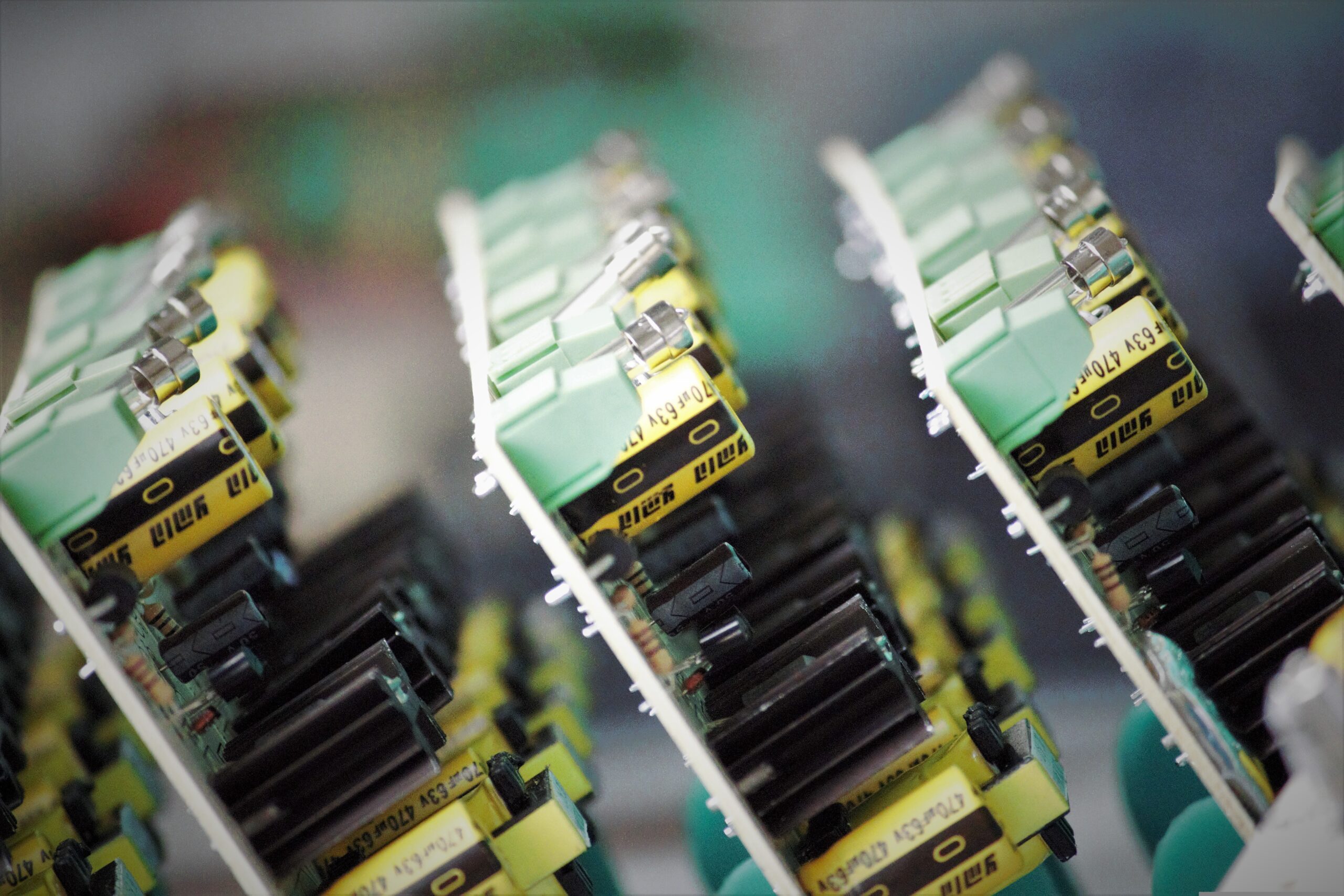

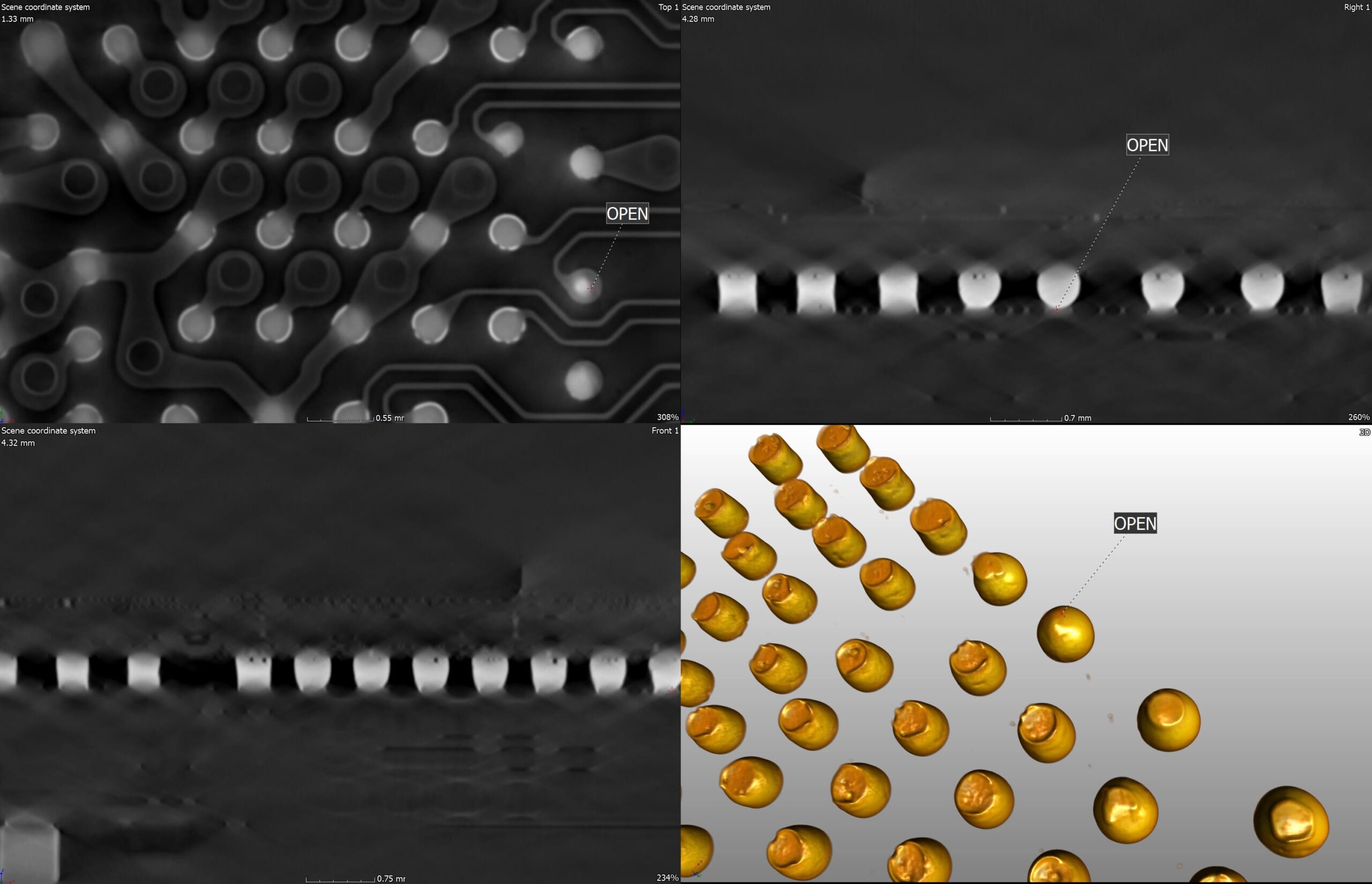

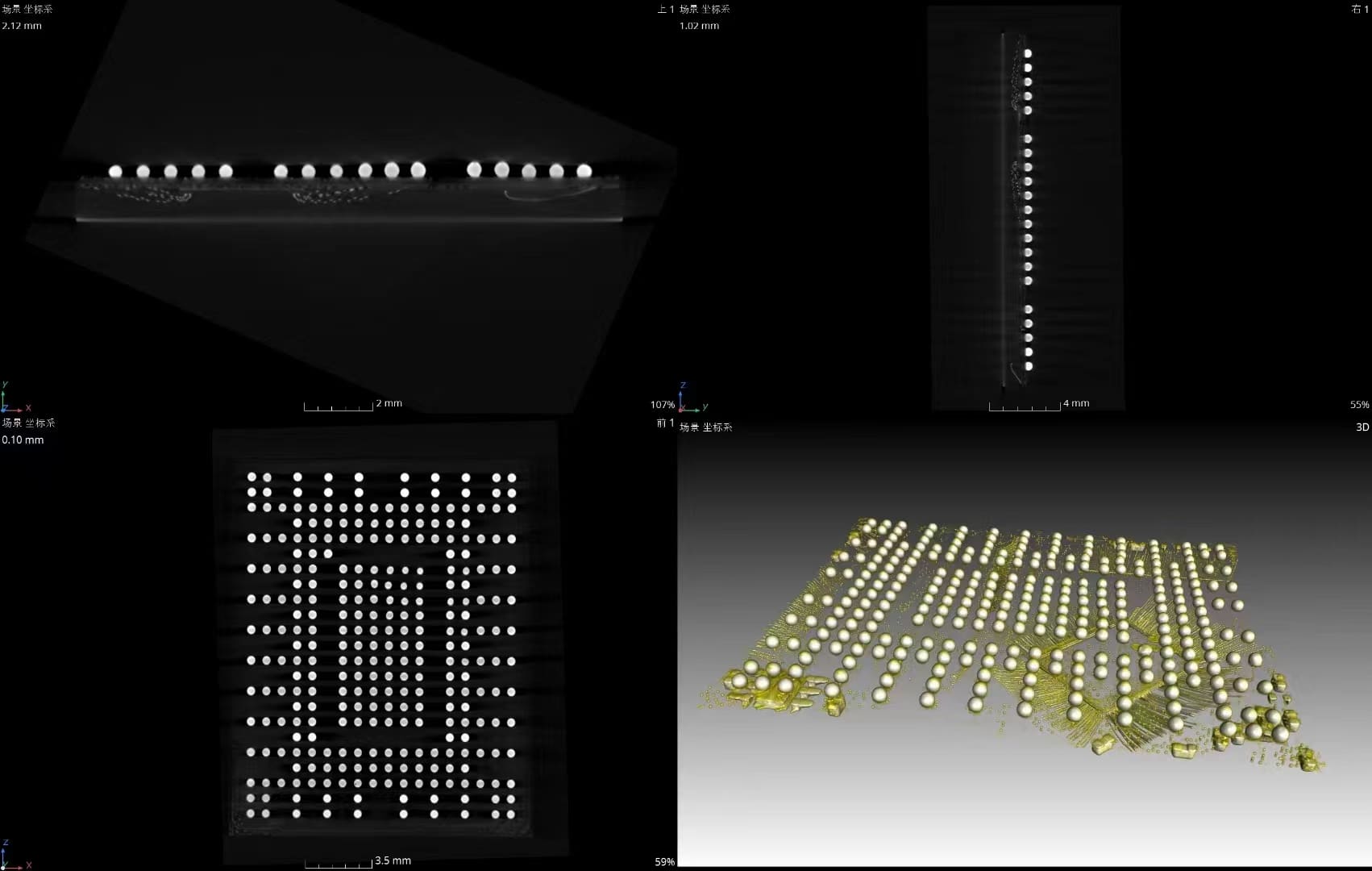

Application Product Samples

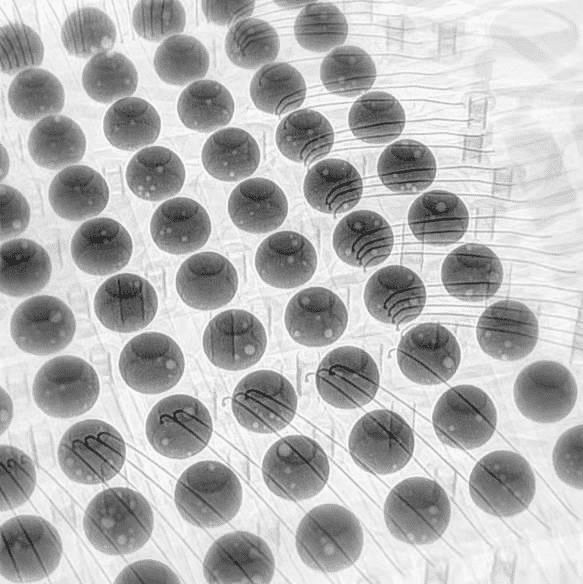

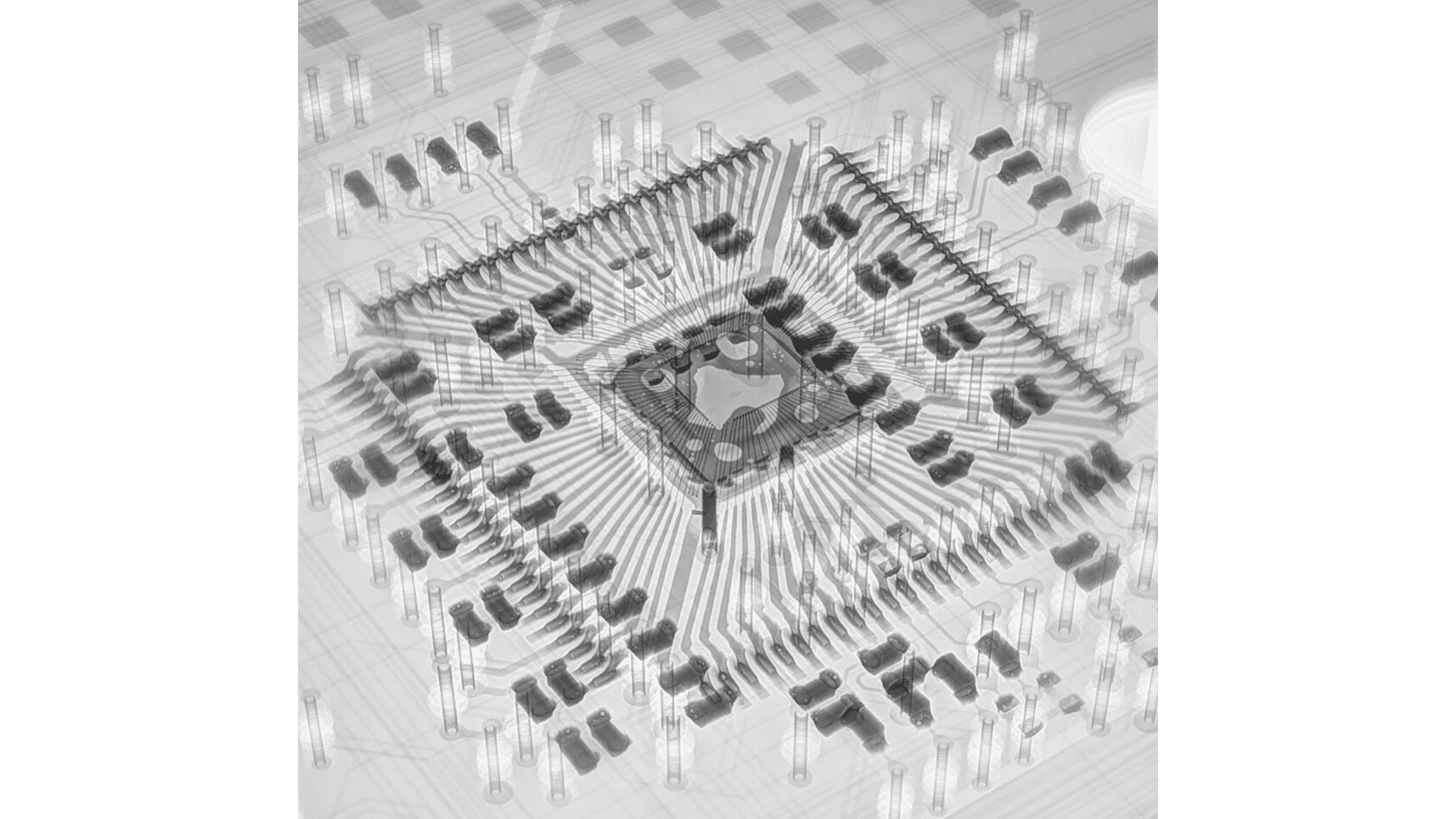

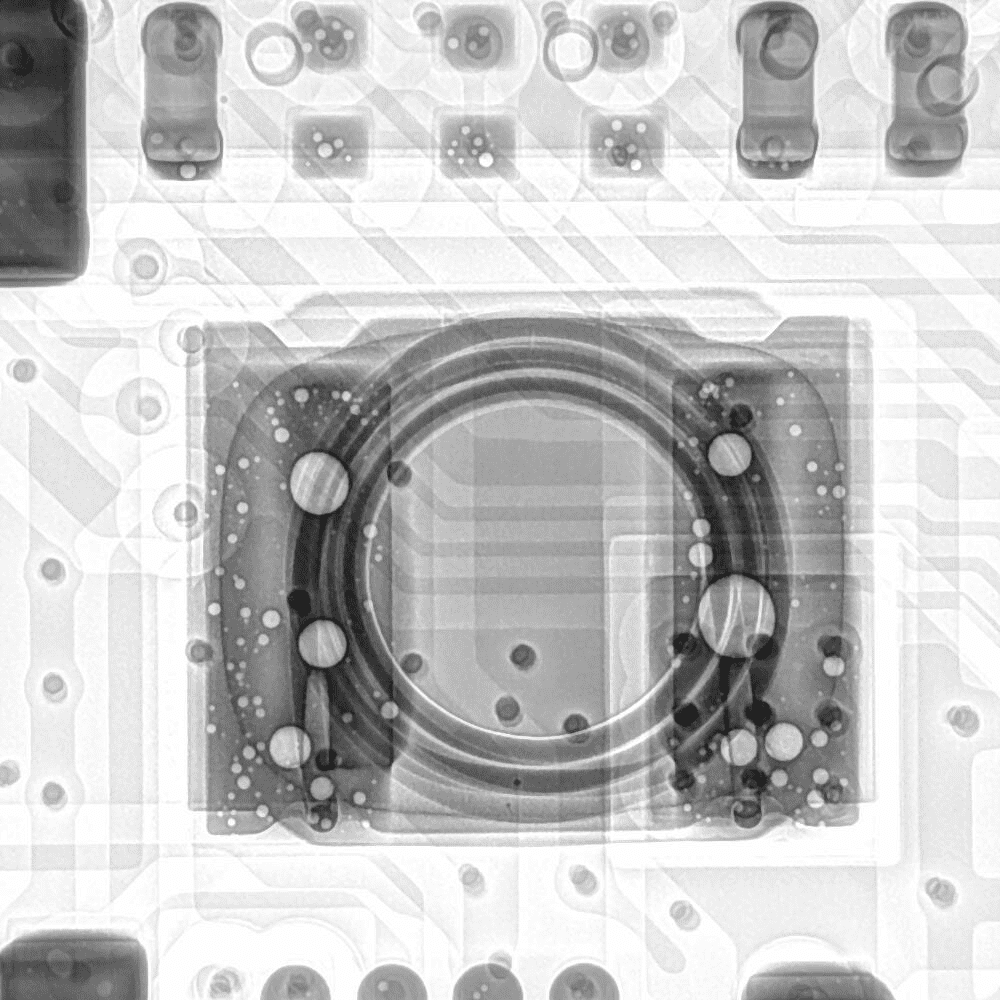

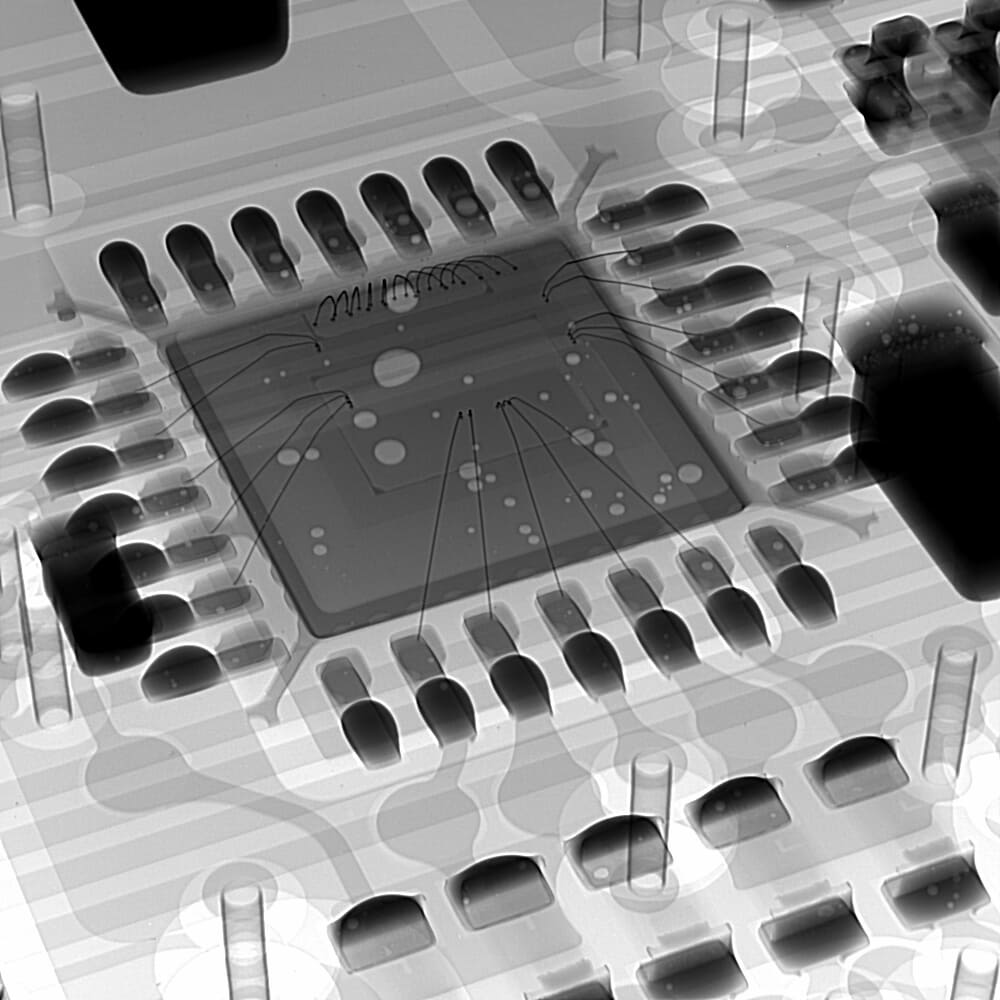

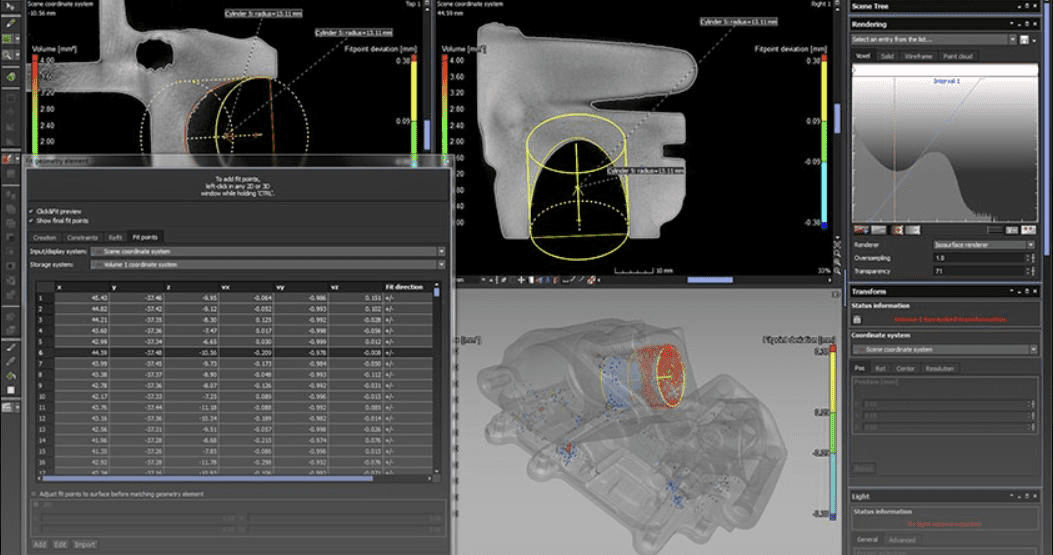

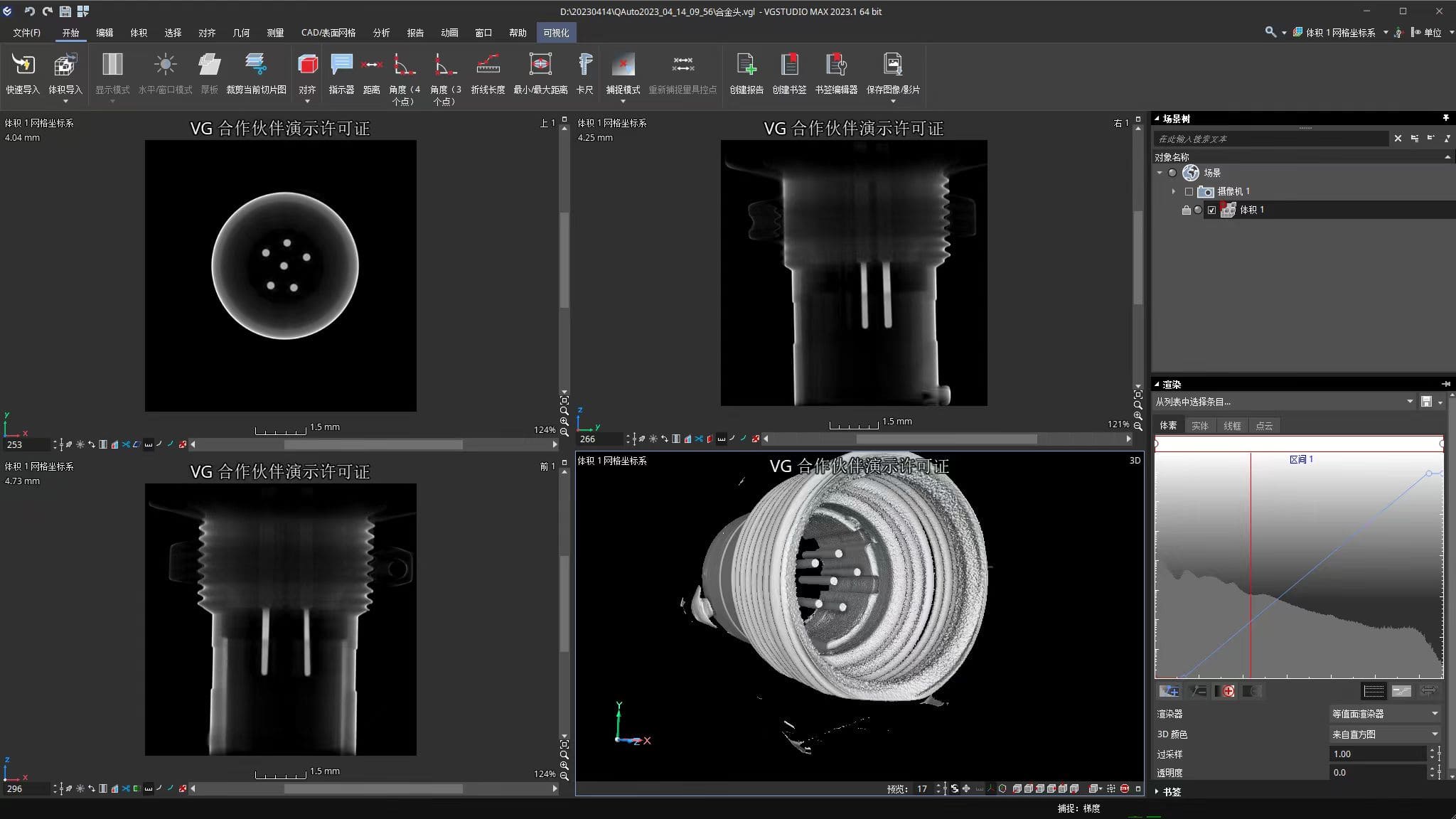

3D X-Ray Images

Detailed Specifications

|

System Magnification and Resolution |

|

|

Geometry Magnification Time |

2100x |

|

Total Magnification |

>23000X |

|

Details Resolution |

Up to 0.35 microns |

|

Submicron X-ray Tube |

Open micron tube, transmission tube head, 170 °radiation Angle, collimation function |

|

Maximum Tube Voltage |

160KV |

|

Maximum Power |

20W |

|

Target |

Non-toxic carrier tungsten target and can be rotated for multiple uses |

|

Vacuum System |

Oil-free low vacuum pump + turbo molecular vacuum pump |

|

Detector |

1536*1536pixel |

|

Control Platform |

X-ray automatic navigation system, can achieve internal and external navigation |

|

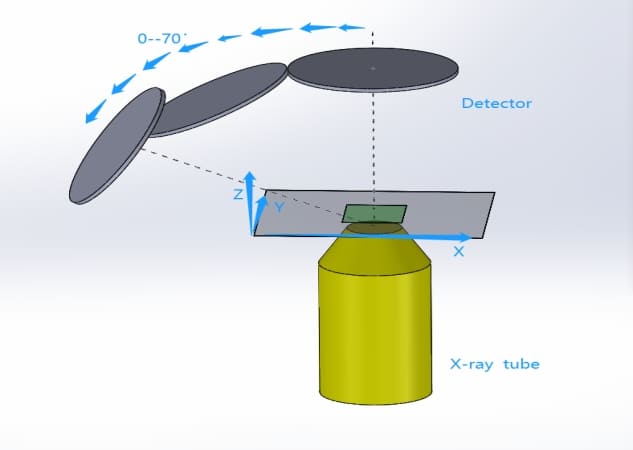

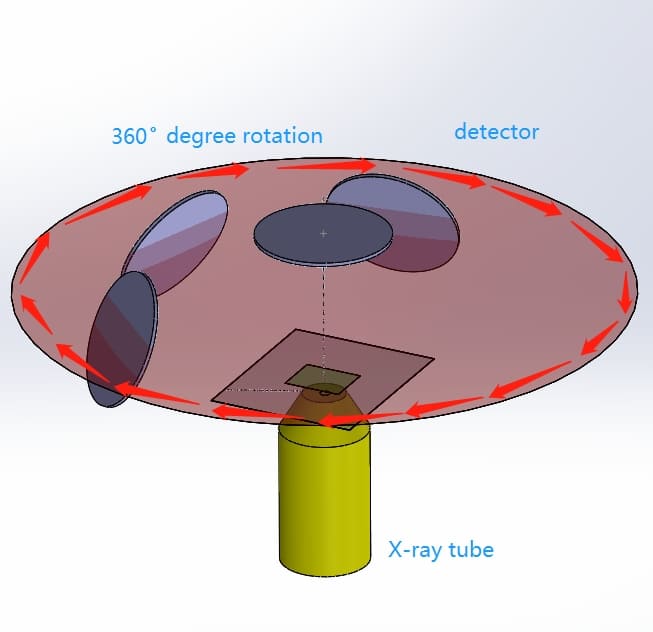

Overall Structure |

High precision anti-vibration, 5-axis synchronous drive |

|

Maximum Detection Range |

410mm×410mm |

|

Maximum Work piece Size/Weight |

510mm×510mm/5kg |

|

Probe WNW Triangle View Rotated |

Adjustable viewing Angle 70°,n×360° |

|

Control |

Joystick control or mouse (manual mode) CNC programming Control(automatic mode) |

|

Control AIDS |

X-ray image navigation map, click to move function, click to enlarge function, Automatically maintain the center of vision function, laser positioning and aiming |

|

Anti-Collision System |

Prevent the test sample from colliding with the ray tube |

|

Image processing software |

|

|

ELT x/act base |

Comprehensive X-ray image analysis software includes image contrast enhancement and filtering. measurement, CNC programming |

|

BGA mode |

BGA solder joint automatic detection function |

|

VC mode |

Automatic calculation of void area ratio, including multi-chip mounting void detection function |

|

System scale (WxHD) |

1650mm*1680mm*1955mm (Excluding console and detachable rear extension) |

|

Console Height Adjustable |

320mm |

|

Maximum Weight |

About 3050kg |

|

Radiation safety protection |

Safety shielding room with lead steel protective structure and lead glass Windows, in accordance with German and American safety design standards for X-ray equipment |

|

Radiation leakage dose rate |

<1.0m Sv/h, in line with international standard |

|

Hardware options |

|

|

Tilt/rotate gear |

Tilt 70° and rotate n × 360* with a maximum workpiece weight of 5kg |

|

Laser posting device |

Cross laser wire |

|

Square non-rotiatng platform |

Test area to 510mm x 510mm |

Contact

+86-18929317246

[email protected]

Our location

3rd floor, Building 3, Yuheng Industrial Park No. 2 (Guangshen Highway), Tantou Community, Songgang, Baoan District, Shenzhen, Guangdong, P. R. China.

Social profiles

Let’s collaborate!

Whether you’re looking for cutting-edge X-ray solutions or expert technical support, our team is here to help. Contact us today to discuss your requirements and discover how ELT can partner with you for success.